You are here:

Interesting information about assembly of components

Interesting information about assembly of components

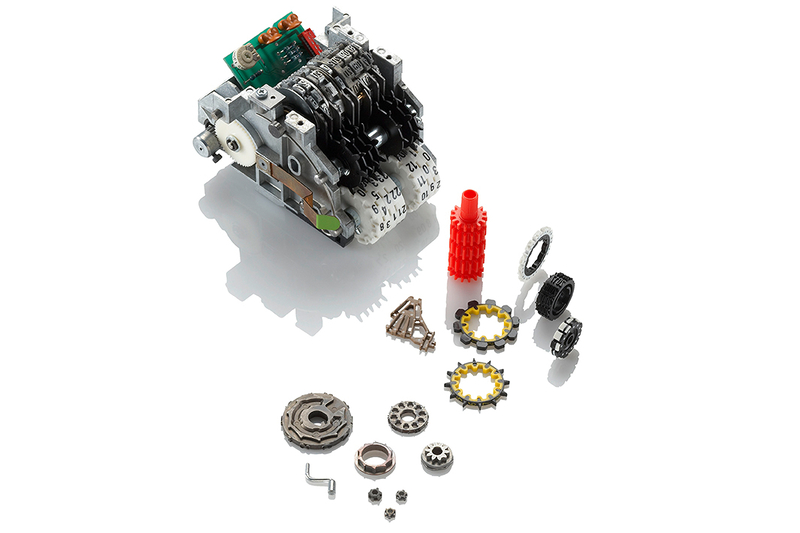

Assembly services for components by REINER® contract manufacturing

Interesting information about assembly of components

Interesting information about assembly of components

This is how the manufacturing of components of precision parts simplifies logistics and increases quality

The most economically successful companies on the market recognised at an early stage that a concentration on core competence would bring decisive competitive advantages. Particularly in the industrial manufacturing of end products in the mechanical engineering and automotive industries, companies hardly produce any individual parts themselves.

Rather, they rely on the expertise and services of specialised parts manufacturers who supply complete components, partially assembled components, system components and assembled individual components for the economic final assembly of the product directly to the production halls.

In the field of precision parts, REINER®'s customers particularly appreciate its technical competence in various manufacturing processes and quality services, its experience in combining production technologies such as MIM (Metal Injection Moulding), zinc die casting, sheet metal components, plastics and its wide range of finishing processes. All of REINER®'s production areas are always geared towards maximum precision.

A unique selling point of REINER® in the assembly of components is the vertical range of manufacturing, which, if required, already begins with the sketch plan. The in-house development centre provides engineers with CAD stations to draw up plans and seamlessly transfer them into component production.

Customers of REINER® can exert influence in every step of the process – and yet always have only one contact person.

REINER® high-precision technology – ideas shaped precisely

Rather, they rely on the expertise and services of specialised parts manufacturers who supply complete components, partially assembled components, system components and assembled individual components for the economic final assembly of the product directly to the production halls.

In the field of precision parts, REINER®'s customers particularly appreciate its technical competence in various manufacturing processes and quality services, its experience in combining production technologies such as MIM (Metal Injection Moulding), zinc die casting, sheet metal components, plastics and its wide range of finishing processes. All of REINER®'s production areas are always geared towards maximum precision.

A unique selling point of REINER® in the assembly of components is the vertical range of manufacturing, which, if required, already begins with the sketch plan. The in-house development centre provides engineers with CAD stations to draw up plans and seamlessly transfer them into component production.

Customers of REINER® can exert influence in every step of the process – and yet always have only one contact person.

REINER® high-precision technology – ideas shaped precisely

What does the assembly of components in contract manufacturing mean for the value chain?

In product development, a company that takes a step back from its own limited possibilities of parts production will always experience a boost in innovation.

A designer's idea is no longer restricted by the fact that his metalworking company, for example, cannot manufacture the required plastic-bearing MIM part including the surrounding mechanism with the required precision. On the contrary: he can rely directly on the know-how of the parts manufacturer REINER® all the way to assembly of components and thus significantly shorten the way from the idea to the production stage.

Time is a decisive factor in global competition. In the production of small series and large series, completed components consisting of individual components always represent a significant time saving in logistics: the professional assembly of a complete component on the component manufacturers’ assembly lines reduces the logistics effort to a minimum.

Also the quality of the component reaches a maximum. At REINER®, all technical production steps are available “in-house” and any necessary optimisations to individual components can be carried out immediately.

When it comes to contract manufacturing of assembly of components, REINER® enjoys a special status. As a manufacturer of high-precision “ready to use” end products, such as hand stamps, electric stamps, digital marking technology and self-service scanners, we know the requirements for the precision of a component and the expectations of its customers very well. Functionality, quality and delivery reliability at REINER® are always seen from the perspective of the customer when looking at the manufacturing of components for small or large series.

A designer's idea is no longer restricted by the fact that his metalworking company, for example, cannot manufacture the required plastic-bearing MIM part including the surrounding mechanism with the required precision. On the contrary: he can rely directly on the know-how of the parts manufacturer REINER® all the way to assembly of components and thus significantly shorten the way from the idea to the production stage.

Time is a decisive factor in global competition. In the production of small series and large series, completed components consisting of individual components always represent a significant time saving in logistics: the professional assembly of a complete component on the component manufacturers’ assembly lines reduces the logistics effort to a minimum.

Also the quality of the component reaches a maximum. At REINER®, all technical production steps are available “in-house” and any necessary optimisations to individual components can be carried out immediately.

When it comes to contract manufacturing of assembly of components, REINER® enjoys a special status. As a manufacturer of high-precision “ready to use” end products, such as hand stamps, electric stamps, digital marking technology and self-service scanners, we know the requirements for the precision of a component and the expectations of its customers very well. Functionality, quality and delivery reliability at REINER® are always seen from the perspective of the customer when looking at the manufacturing of components for small or large series.

Precision parts in the component assembly – what is the perfect manufacturing process for the assembly of components?

Assigning orders for the assembly of components requires a high degree of confidence of the customer in the contract manufacturing of the contractor. For decades, REINER®'s customers have successfully placed their trust in the manufacturing of individual components, partially assembled components, system components and complex components. Responsibilities are clearly defined, which are handled by a single contact person in all aspects of the professional assembly of a component.

The “optimal manufacturing process” for the assembly of components should do without unnecessary logistics, storage times and processing efforts with various parts suppliers and contact persons. Metaphorically speaking: the various parts required come directly from the production lines to an assembly line in the hands of experienced specialists for immediate assembly of the component.

With its quality services, REINER® is also a reliable partner in the pure assembly of components from provided or purchased individual components up to the assembly of the end product.

Moreover, what distinguishes the “perfect contractor” for contract manufacturing and the manufacture of components is the handling of the “unforeseen” in small series and large series production. This includes short-term development corrections by the customer, necessary quick reactions to fluctuations in the number of pieces required, flexible handling of delivery bottlenecks, acceptance of final assemblies and more.

As a partner, REINER® actively supports its customers in the accomplishment of these tasks.

The wide range of services offered by REINER® Precision Technology “in-house” virtually covers all necessary technologies for manufacturing components:

The “optimal manufacturing process” for the assembly of components should do without unnecessary logistics, storage times and processing efforts with various parts suppliers and contact persons. Metaphorically speaking: the various parts required come directly from the production lines to an assembly line in the hands of experienced specialists for immediate assembly of the component.

With its quality services, REINER® is also a reliable partner in the pure assembly of components from provided or purchased individual components up to the assembly of the end product.

Moreover, what distinguishes the “perfect contractor” for contract manufacturing and the manufacture of components is the handling of the “unforeseen” in small series and large series production. This includes short-term development corrections by the customer, necessary quick reactions to fluctuations in the number of pieces required, flexible handling of delivery bottlenecks, acceptance of final assemblies and more.

As a partner, REINER® actively supports its customers in the accomplishment of these tasks.

The wide range of services offered by REINER® Precision Technology “in-house” virtually covers all necessary technologies for manufacturing components:

Capability Overview

| Zinc die casting | for small, particularly resistant parts |

| Metal Injection Moulding | for precision parts with complex geometries |

| Fine blanking/forming | for sheet metal parts with high precision requirements |

| In-house tool shop | for fineblanking tools and forming tools |

| Surface finish | Sandblasting, barrel finishing, polishing, lapping |

| Coating technology | Thin film technology, electroplating, painting |

| Joining technology | Laser welding, soldering, assembly |

| Heat treatment | Hardening, HIP (hot isostatic pressing) |

| Machining | Turning, milling, drilling, grinding, reaming, honing, thread cutting |

| Forming technology | Calibration |

Contact & offer

Do you have any questions or need more information?

I look forward to hearing from you!

Matthias Schneider - Regional Sales Manager

+49 7723 657-300

Matthias.Schneider@reiner.de

Request a quote

Does outsourced manufacturing of components have any advantages compared to the assembly of components in the company's own final finishing line?

The higher the degree of completion of a component supplied, the greater the economic advantage for the customer of contract manufacturing of an external component assembly. Most parts in modern technical products require specific manufacturing know-how and extensive machinery. Professional assembly of the parts to a component requires trained and experienced personnel.

REINER®'s contract manufacturing of components benefits its customers in many ways:

REINER®'s contract manufacturing of components benefits its customers in many ways:

- A smaller number of suppliers and contact persons significantly reduces the administrative and processing effort.

- Logistics costs are reduced and inefficiencies, time and costs are saved.

- Quality inspection is noticeably simplified, as REINER® already guarantees the functionality of its components.

- The finishing process is shortened to the assembly of a few, quality-checked components, which reduces the required personnel (and partly also the requirements for their qualification).

- Such cost savings go hand in hand with significantly greater flexibility in technical solutions and materials used.

What special services make REINER® unique in the assembly of components in the field of mechanical engineering?

REINER®, the specialist for precision parts from Furtwangen in the Black Forest, is a convincing choice due to its vertical range of manufacture and broad spectrum of “in-house” manufacturing technologies:

- Consulting know-how through over 100 years of in-house development and final production

- Solution know-how from our own CAD tool design department

- Manufacturing know-how in zinc die casting, metal injection moulding, fine stamping, fine blanking, CNC further processing

- Post-processing know-how in surface finishing, coating technologies, joining technology, heat treatment, machining

- Forming technology

- Combined know-how of production technologies, e.g. for MIM parts with plastic bearings, zinc die casting parts with plastic encapsulation, sheet metal parts, hybrid parts with welded-on steel components, 2-component plastic injection moulded parts ...

To what extent does REINER® add value in the manufacturing of components?

When manufacturing a component, the services of REINER® contract manufacturing range from individual components to the complete product manufacturing process, thus from tool design to final assembly. REINER® also offers a large number of individual intermediary production steps within its contract manufacturing services. When precision parts are involved, REINER is the first choice partner for assembled individual components, pre-assembly of parts, partially assembled components, complete components, system components and even complex components.