You are here:

Interesting facts about laser-cutting

REINER® contract manufacturing with laser cutting

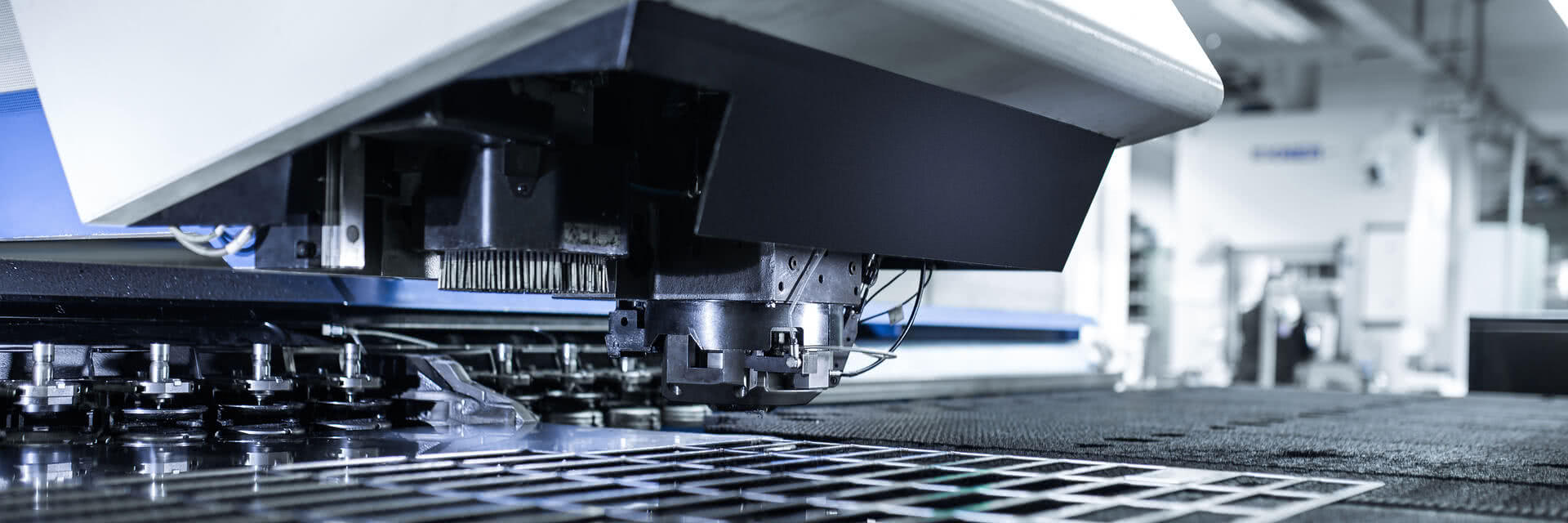

Sheet metal laser cutting to precision parts up to 4 mm thick

The power of light has always fascinated people. It has inspired imagination and inventive spirit. In the last century, bundled light beams were a subject of science fiction novels and films like Star Wars. In the 1960s, the first semi-conductor lasers were developed, marking the scientific launch of today's industrial application.

With the clear increase of laser outputs of up to 20 kW, laser cutting has become one of the most important cutting methods in metal processing. Metal cutting by laser combines high processing speeds with extremely precise cuts – no longer needing the usual tool shop expenditures known from presses. Laser cutting is mostly used for sheet processing in smaller batches.

REINER® precision technology – precisely shaped ideas

With the clear increase of laser outputs of up to 20 kW, laser cutting has become one of the most important cutting methods in metal processing. Metal cutting by laser combines high processing speeds with extremely precise cuts – no longer needing the usual tool shop expenditures known from presses. Laser cutting is mostly used for sheet processing in smaller batches.

REINER® precision technology – precisely shaped ideas

Competence Matrix

| Core Technologies Technical Features | Laser cutting / NC bending processes |

|---|---|

| Dimensions Laser | 1,000 x 2,000 mm; NC-bending up to 1000 mm |

| Sheet thickness | 0.5 mm to max. 4 mm sheet thickness |

| Materials | 16MnCr5, C45, X5CRNI18-10, ALMG3, DC01, and DC04 |

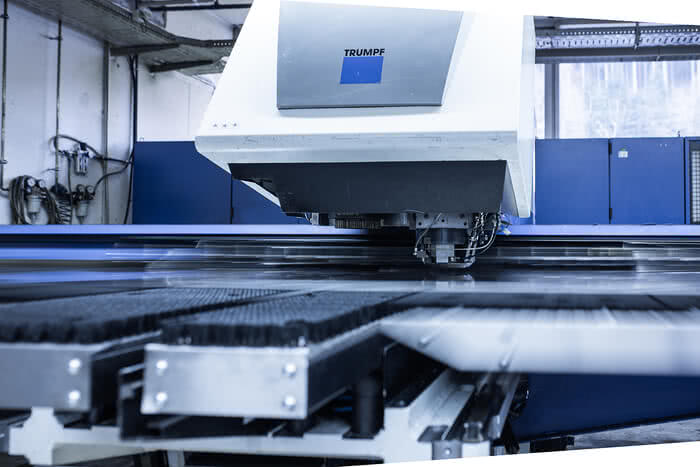

| Machine type | Trumpf punching/laser cutting machine, and TruBend – NC-bending press |

| Batch sizes | From 100 pcs. onwards |

| Special technology features | • Economically efficient production of smaller batch sizes • No tools are needed for laser cutting contours |

| Special REINER® features | Many years of experience in state of the art CNC processing centres for complete/final processing, heat and surface processing by reliable partners |

| Special knowhow | • Special forms of the machine can be produced • Thread-cutting for punching/laser process |

In what kind of contract manufacturing is laser cutting of metal particularly economical?

Laser cutting comes with attractive costs, since no expensive tools are required, and equipment costs are lower. Sheet processing is economically possible even at very small lot sizes. Laser cutting derives its potential from the low focus diameter of the laser beam and the resulting narrow cutting gap, high infeed speeds and minimal heat effect on the material.

How does laser cutting work?

Laser cutting means cutting material panels with a laser. At REINER®, these panels are metal sheets, stainless steel or aluminium at thicknesses of 0.5 mm to 4 mm. A focused and high-energy laser beam is pointed at these panels, strong enough to melt and evaporate the material upon impact, until the metal is separated, and the cut is made. The resulting metal vapour is blown out with special gases and high pressure.

Contact & offer

Do you have any questions or need more information?

I look forward to hearing from you!

Matthias Schneider - Regional Sales Manager

+49 7723 657-300

Matthias.Schneider@reiner.de

Request a quote

What materials does REINER® process in laser cutting?

Stainless steel laser cutting

Case-hardening steel 16MnCr5 (Euro norm: EC80)

Case-hardening steels are mostly used in mechanical engineering for parts subject to greater stress with a higher core strength, e.g. for measuring tools, joints and gears. Case-hardening steel has a hard edge layer and a tough core produced by case hardening.

Tempered steel C45E (formerly: CK45 / DIN 1.1191)

This steel is suitable for dynamically stressed laser-cut parts in machine and tool construction, since it is very tough and tension-resilient. It is tempered by transformation hardening. The carbon share is between 0.2 and 0.65% and the material properties are controlled specifically by alloys with chromium, manganese, nickel and molybdenum.

Non-corrosive austenitic steel X5CRNI18-10

Austenitic, acid-resistant Cr-Ni-steel is predestined for use in environments with water, steam, food acids, etc. It can be found in facilities from the food, pharmaceutical and cosmetic industries, medicine and façade technology. It has an extremely low carbon content, which increases resilience to intercrystalline corrosion and keeps the hardness, strength and yield strength in the quenched condition particularly low. Stainless steel laser parts can be polished very well and are particularly suitable for cold-forming.

Laser-cutting sheet metal

Cold-rolled thin steel sheet DC01/DC04 (Euro norm: EN 10130)

These sheets are among the "soft" steels that are often used in automotive construction and in consumer goods. They are characterised by consistent quality and narrower thickness tolerance as compared to hot-rolled sheets.

Laser-cutting aluminium

Aluminium alloy AlMg3 (Euro norm: EN AW 5754)

This alloy combines many benefits, such as medium strength, good forming capacity and good corrosion resistance. Laser-cut parts of the aluminium alloy AlMg3 are used at lower demands to mechanical resilience.

Further materials on request – contact us.

Further materials on request – contact us.

How precise is CNC laser cutting?

The light beam hits the material with an extreme focus and creates a very narrow cut. A cutting gap or cutting joint develops a very smooth cutting edge that can be defined in a targeted manner. This processing method not only permits highly precise cutting of sheets, but also cutting in any shape and with inner recesses. The computer-controlled cutting lasers at REINER® produce very fine contours for high-precision components of thin metal or metal up to 4 mm thick.

Does laser cutting require post-processing?

CNC laser cutters achieve higher cutting speeds and smooth cutting edges that do not usually require any further post-processing in the material thicknesses processed by REINER®. Downstream heat and surface treatment are produced by reliable cooperation partners and absolute specialists in the respective areas for REINER®.

What are the advantages and disadvantages to laser cutting?

A laser is a highly flexible, computer-controlled tool that requires no pressing tools for forming. Sheet processing can start with simple vector data for the desired shape. The laser can cut virtually any solid body with laser beams and the resulting evaporation of the material. The laser cuts wood, plastics and CFK or even steel, sheet metal and aluminium. We at REINER® specialise in laser cutting of metal.

Another special feature of laser-cutting sheet metal is the high material utilisation. Further processing steps such as laser engraving can be performed in another processing step. Since the cutting method is contact-free, laser cutting machines barely suffer any wear. Dust load and material waste are reduced as compared to CNC milling or metal pressing. The material to be processed does not need to be fastened as hard as, e.g., when pressing, which protects the metal sheets.

On the flip side, sheet processing by CNC laser cutting consumes a lot of gas (for blowing out the metal vapours) and power (for the high-energy laser). The industrial safety measures required are more elaborate than in machining or pressing.

Another special feature of laser-cutting sheet metal is the high material utilisation. Further processing steps such as laser engraving can be performed in another processing step. Since the cutting method is contact-free, laser cutting machines barely suffer any wear. Dust load and material waste are reduced as compared to CNC milling or metal pressing. The material to be processed does not need to be fastened as hard as, e.g., when pressing, which protects the metal sheets.

On the flip side, sheet processing by CNC laser cutting consumes a lot of gas (for blowing out the metal vapours) and power (for the high-energy laser). The industrial safety measures required are more elaborate than in machining or pressing.

What are the essential differences between laser-cutting and pressing?

A CNC laser cutter usually comprises of a single laser source that must "run across" the entire route of the workpiece to be cut. A press can usually eject 10 or even as many as 100 parts from a sheet at the same time. As a result of this, laser cutting is barely suitable for mass production

The more complex the shape of a high-precision part and the smaller the required piece number, the more economically efficient sheet laser-cutting will be. Tool costs make up an essential share in fine blanking, but do not arise in laser cutting. The workpiece contours are loaded directly and digitally into the CNC laser cutter, which can start its work virtually without delay after programming.

The more complex the shape of a high-precision part and the smaller the required piece number, the more economically efficient sheet laser-cutting will be. Tool costs make up an essential share in fine blanking, but do not arise in laser cutting. The workpiece contours are loaded directly and digitally into the CNC laser cutter, which can start its work virtually without delay after programming.

Why is REINER® one of the top companies among laser cutter providers?

The REINER® brand is known as a leading manufacturer of long-lived stamps, marking devices and self-service scanners. For more than a century, REINER® has therefore been posing special demands to the small and often complex high-precision parts needed for its offering.

In addition to economic efficiency and flexibility in production, robustness of each part guarantees longevity and high quality of the finished product. This is and remains a central pillar of the corporate philosophy at REINER® in 2024 as well. The company from the Black Forest continues to be a leading manufacturer of delicate and precise parts by sheet laser-cutting and metal laser-cutting in Germany.

In addition to economic efficiency and flexibility in production, robustness of each part guarantees longevity and high quality of the finished product. This is and remains a central pillar of the corporate philosophy at REINER® in 2024 as well. The company from the Black Forest continues to be a leading manufacturer of delicate and precise parts by sheet laser-cutting and metal laser-cutting in Germany.