You are here:

Questions and answers on plastic injection moulding

Questions and answers on plastic injection moulding

REINER® as plastic injection moulding manufacturer

Injection moulding of precision parts at the highest level

Plastic injection moulding offers almost unlimited design freedom in terms of geometry and materials. A large number of plastics with very different properties are available, which can even be combined in multi-component injection moulding. Even undercuts, bores, cross holes, threads, lamellas and relief structures and engravings (e.g. logo, article number) can be produced in a single injection moulding production process and with the highest degree of fineness.

REINER® Präzisionstechnik is your competent partner and convinces by the following characteristics:

• Wide range of applications (medicine, hand-/power tools, aerospace, defence industry, sensor technology, locking technology)

• Complex geometries with cross holes, threads, lamellas, gear wheels

• Large selection of surface structures

• Controllable material properties due to different plastics and multi-component injection moulding

• Cost-effective production of high-volume components

• Production takes place with little material waste

• REINER® manufactures the injection moulding tool with its own in-house tool design

• Many years of experience in mould and tool making.

REINER® precision technology – precisely shaped ideas

REINER® Präzisionstechnik is your competent partner and convinces by the following characteristics:

• Wide range of applications (medicine, hand-/power tools, aerospace, defence industry, sensor technology, locking technology)

• Complex geometries with cross holes, threads, lamellas, gear wheels

• Large selection of surface structures

• Controllable material properties due to different plastics and multi-component injection moulding

• Cost-effective production of high-volume components

• Production takes place with little material waste

• REINER® manufactures the injection moulding tool with its own in-house tool design

• Many years of experience in mould and tool making.

REINER® precision technology – precisely shaped ideas

Competence overview

| Dimensions/tool | 700x700mm tool clamping surface |

|---|---|

| Part weight | ≤ 300g |

| Materials | POM, PUR, PC, PMMA, PE, ABS, other materials on request |

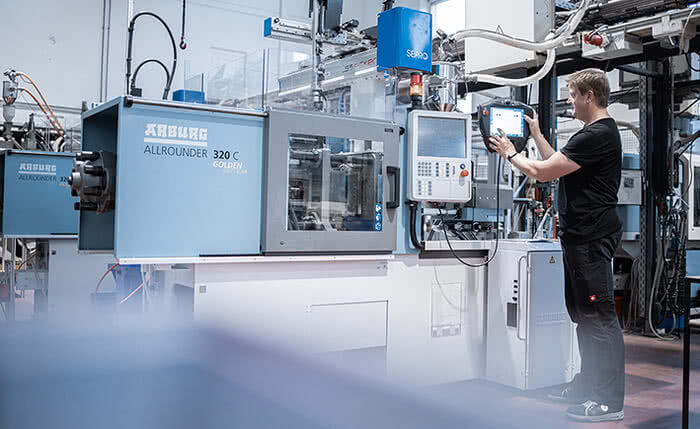

| Machine type | Arburg, closing forces up to 150 t |

| Lot sizes | from 10.000 pcs. |

| Special features of technology | • Wide range of applications (medicine, hand-/power tools, aerospace, defence industry, sensor technology, locking technology) • Complex geometries with cross holes, threads, lamellas • Cost-effective production of high-volume components • Many material alternatives • Production is carried out with little material waste, little reworking or finishing work |

| Special features of REINER® | • Own tool design / mould and tool making • Many years of experience in parts production• Mould flow analysis |

| Special know-how | • Focus on small / technical parts • 2 component injection moulding also possible |

Injection moulding: What's that?

We encounter products from the injection moulding process in everyday life on almost all articles of daily use: From the closure of the milk carton to the buttons on the computer to the detergent drawer.

Not to forget the millions of “hidden stars” of small parts that are tiny components in electrical and mechanical devices that ensure smooth operation.

In the volume production of medium and large series, the advantages of plastic injection moulding are fully exploited in terms of quantities and unit price: The finished part is produced directly from the raw material, in many cases without further processing.

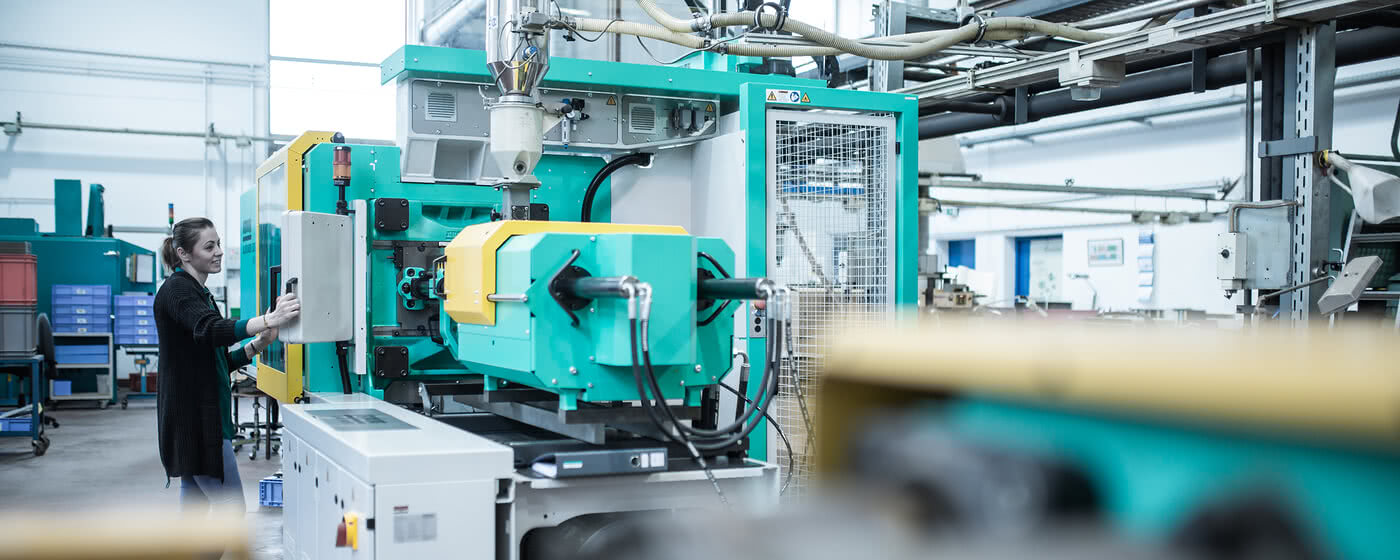

The injection moulding process is therefore one of the most frequently used production processes for plastics. In the injection moulding process, plastic granulates, plastic powders or elastomers are first liquefied. These – depending on the material composition – thermoplastics polymers are then injected into the mould cavity of the injection mould. They are solidified in the mould and then ejected.

The production process is highly suitable for manufacturing complex moulded parts as mass-produced articles and achieves a high degree of continuous accuracy for every part produced. The sizes and weights of the desired injection moulded parts are extremely variable, from a thousandth of a gram to several kilograms, from the tiny gear wheel to the trash can. We at REINER® have specialised in precision parts with a maximum part weight of 300 grams.

Not to forget the millions of “hidden stars” of small parts that are tiny components in electrical and mechanical devices that ensure smooth operation.

In the volume production of medium and large series, the advantages of plastic injection moulding are fully exploited in terms of quantities and unit price: The finished part is produced directly from the raw material, in many cases without further processing.

The injection moulding process is therefore one of the most frequently used production processes for plastics. In the injection moulding process, plastic granulates, plastic powders or elastomers are first liquefied. These – depending on the material composition – thermoplastics polymers are then injected into the mould cavity of the injection mould. They are solidified in the mould and then ejected.

The production process is highly suitable for manufacturing complex moulded parts as mass-produced articles and achieves a high degree of continuous accuracy for every part produced. The sizes and weights of the desired injection moulded parts are extremely variable, from a thousandth of a gram to several kilograms, from the tiny gear wheel to the trash can. We at REINER® have specialised in precision parts with a maximum part weight of 300 grams.

Contact & offer

Do you have any questions or need more information?

I look forward to hearing from you!

Matthias Schneider - Regional Sales Manager

+49 7723 657-300

Matthias.Schneider@reiner.de

Request a quote

Which injection moulded parts show REINER®'s competence particularly clearly?

Housing parts, gears

Which plastic achieves which material properties through injection moulding?

• Polyolefins such as polypropylene produce to a certain extent elastic mouldings

• Plexiglass (PMMA) and polycarbonate (PC) become transparent as moulded parts, such as display screens

• Polystyrene (PS) and others are used in many toys with harder properties, such as LEGO bricks and household appliances.

• Polyamide (PA), polyoxymethylene (POM) and other engineering plastics can be found in mechanical and electrical engineering.

• Plexiglass (PMMA) and polycarbonate (PC) become transparent as moulded parts, such as display screens

• Polystyrene (PS) and others are used in many toys with harder properties, such as LEGO bricks and household appliances.

• Polyamide (PA), polyoxymethylene (POM) and other engineering plastics can be found in mechanical and electrical engineering.

How does production in thermoset injection moulding differ from that in thermoplastic injection moulding?

At the core, the plastics differ in the process required to cause them to solidify. While thermosetting plastic hardens by heating to approx. 130° - 250° Celsius, heated thermoplastics must be solidified by cooling in the mould.

In thermoset injection moulding, the material in the cylinder is first heated to below 110° Celsius and injected into the mould. Then the mould is heated to 130° - 250° and the moulding compound hardens by cross-linking. Another special feature of thermoset is that the moulded part cannot be remelted in order to be reused. Cured thermoset injection moulded parts can only be recycled.

In the process used by REINER®, thermoplastic injection moulding, the heated material is pressed under high pressure into the mould, which is also heated. The moulded part solidifies and can be ejected by cooling the mould. The properties of the plastics used, such as polypropylene, plexiglass (PMMA), polycarbonate (PC), polystyrene (PS), polyamide (PA), polyoxymethylene (POM) and others, are often adjusted by additives and fillers. These can be glass beads or glass fibres, for example.

Multi-component injection moulding (2-component injection moulding) makes it possible to produce individual parts with several material properties from two or more different plastics in a single operation. In the simplest case, the plastics differ only in colour. Combinations are particularly interesting because of their different physical, elastic or haptic properties. We all hold an example in our hands in the morning: Toothbrushes are made of a smooth plastic material, but a softer material with a better grip is often used only at the point of contact.

In thermoset injection moulding, the material in the cylinder is first heated to below 110° Celsius and injected into the mould. Then the mould is heated to 130° - 250° and the moulding compound hardens by cross-linking. Another special feature of thermoset is that the moulded part cannot be remelted in order to be reused. Cured thermoset injection moulded parts can only be recycled.

In the process used by REINER®, thermoplastic injection moulding, the heated material is pressed under high pressure into the mould, which is also heated. The moulded part solidifies and can be ejected by cooling the mould. The properties of the plastics used, such as polypropylene, plexiglass (PMMA), polycarbonate (PC), polystyrene (PS), polyamide (PA), polyoxymethylene (POM) and others, are often adjusted by additives and fillers. These can be glass beads or glass fibres, for example.

Multi-component injection moulding (2-component injection moulding) makes it possible to produce individual parts with several material properties from two or more different plastics in a single operation. In the simplest case, the plastics differ only in colour. Combinations are particularly interesting because of their different physical, elastic or haptic properties. We all hold an example in our hands in the morning: Toothbrushes are made of a smooth plastic material, but a softer material with a better grip is often used only at the point of contact.

What does tool and mould making have to take into account when manufacturing injection moulds?

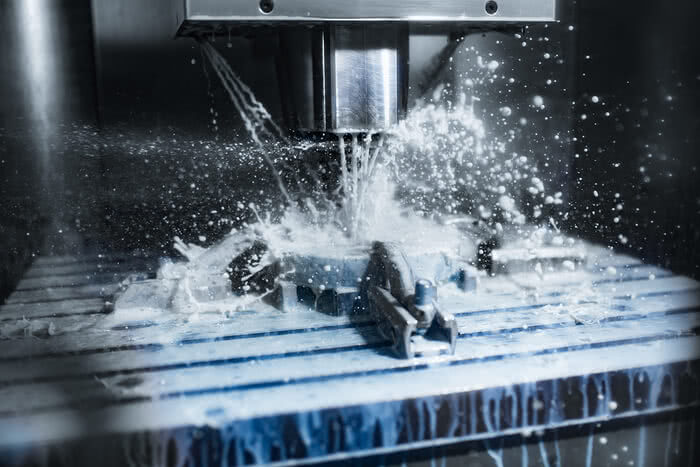

The most commonly used injection moulding process is thermoplastic injection moulding, in which the heated material hardens as it cools. However, the cooling also makes the moulded part somewhat smaller. This makes it easier to remove it from the mould indeed. However, this “shrinkage” must already be calculated exactly during the construction of the tool and included in the mould construction.

The engineer in tool and mould making must already plan the mechanisms for removing the moulded part with great foresight during the design phase, depending on the complexity of the required injection moulded part. In addition to conventional ejectors, flat ejectors and scrapers, he also knows sliders and transverse ejectors.

Complex moulded parts with “inner life” are solved with thread cores or collapsible cores.

Aluminium and steel are used as materials for the production of the tools themselves. Aluminium is cheaper in small series production, but also less dimensionally stable and resistant than steel. The significantly harder, but also more complex tool material steel allows for more special surface structures and higher quantities.

The engineer in tool and mould making must already plan the mechanisms for removing the moulded part with great foresight during the design phase, depending on the complexity of the required injection moulded part. In addition to conventional ejectors, flat ejectors and scrapers, he also knows sliders and transverse ejectors.

Complex moulded parts with “inner life” are solved with thread cores or collapsible cores.

Aluminium and steel are used as materials for the production of the tools themselves. Aluminium is cheaper in small series production, but also less dimensionally stable and resistant than steel. The significantly harder, but also more complex tool material steel allows for more special surface structures and higher quantities.

What are the advantages of injection moulding?

The success story of plastic in our everyday life as a mass-produced article can be attributed to the injection moulding process. An essential advantage of injection moulding is the ability to produce an immediately usable moulded part from a raw material (usually a plastic granulate) by means of temperature and pressure in a single operation.

This makes this production process ideal and complete for automation. In particular, the production of very small components is extremely simplified by injection moulding. At the same time it enables high-precision individual parts in series production with constant quality.

This makes this production process ideal and complete for automation. In particular, the production of very small components is extremely simplified by injection moulding. At the same time it enables high-precision individual parts in series production with constant quality.

What influences the plastic injection moulding costs?

Well planned is half built, this also applies to the tool design for injection moulding. Depending on the complexity of the moulded part, the tool shop accounts for 20 - 40% of the budget. The larger item is the mould inserts, which can account for 60 - 80 % of the costs.

In production itself, the plastic used is a factor. It is therefore always part of our advice at REINER® to find the best possible material with the most favourable costs for you on the basis of your requirements in terms of strength and functionality.

In production itself, the plastic used is a factor. It is therefore always part of our advice at REINER® to find the best possible material with the most favourable costs for you on the basis of your requirements in terms of strength and functionality.

Why is REINER® one of the top injection moulding companies in the field of precision parts?

The REINER® brand is known as a leading manufacturer of durable stamps, marking devices and self-service scanners. For over 100 years, REINER® has made special demands on the small and often complex precision components required for this. In addition to cost-effectiveness and flexibility in production, the robustness of each component guarantees the longevity and high quality of the finished product. This claim is also a central pillar of REINER®'s corporate philosophy in the year 2024. The factory in the Black Forest thus continues to be one of the leading manufacturers of filigree and precise plastic injection moulded parts in Germany.

This experience benefits not only REINER®'s own product portfolio, but also a large number of external customers from a wide variety of industries: Medicine, hand-/power tools, aerospace, defence industry, sensor technology, locking technology etc.

Whenever innovative precision parts are required to solve technical challenges, a complex design or outstanding material properties are required, REINER® injection moulding in plastic is the first engineering choice.

This experience benefits not only REINER®'s own product portfolio, but also a large number of external customers from a wide variety of industries: Medicine, hand-/power tools, aerospace, defence industry, sensor technology, locking technology etc.

Whenever innovative precision parts are required to solve technical challenges, a complex design or outstanding material properties are required, REINER® injection moulding in plastic is the first engineering choice.

What qualifies REINER® especially as a plastic injection moulding parts manufacturer?

REINER® has its own tool construction with many years of experience. Our employees in mould making and tool construction have acquired solution know-how in the planning and construction of injection moulds for small and technical parts. In the most modern CNC machining centres, the injection moulded parts receive their finish in complete and final operation.

REINER® plastic injection moulding – quality from the heart of Baden-Wuerttemberg

The company REINER® has had its headquarters in Furtwangen in the Black Forest since 1913 and is one of the market leaders for hand stamps in Europe as well as for mobile inkjet printers and scan systems in Germany.

Many customers attach importance to the physical proximity to their injection moulded parts manufacturer. Manufacturing companies in Baden-Wuerttemberg (BW) and southern Germany, but also in neighbouring France / Alsace, Switzerland and Austria rely on REINER®'s expertise in injection moulding tools and plastic series production.

REINER® Precision Technology – Ideas precisely put into shape

Many customers attach importance to the physical proximity to their injection moulded parts manufacturer. Manufacturing companies in Baden-Wuerttemberg (BW) and southern Germany, but also in neighbouring France / Alsace, Switzerland and Austria rely on REINER®'s expertise in injection moulding tools and plastic series production.

REINER® Precision Technology – Ideas precisely put into shape