You are here:

Precision parts manufacturing from the high-tech region of the Black Forest REINER® Precision Technology

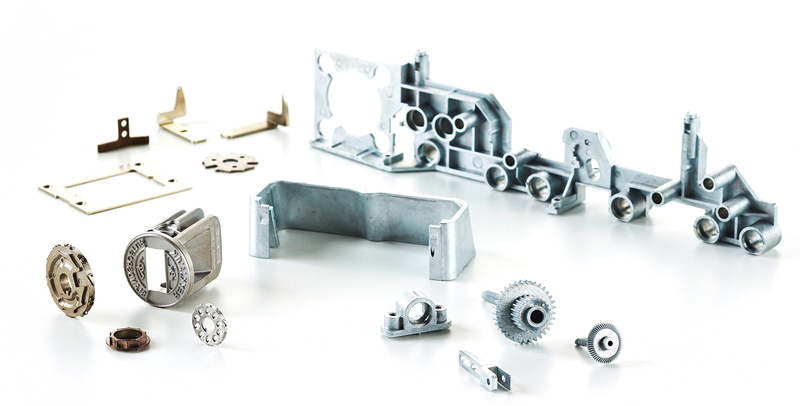

In the production of precision parts, REINER® precision technology offers tailor-made solutions at the highest quality level – Made in Germany.

For the production of your individual precision parts we have a wide range of manufacturing technologies with modern machinery.at our Furtwangen headquarters – in the heart of Baden-Wuerttemberg.

REINER® contract manufacturing covers all relevant manufacturing processes for zinc die casting, injection moulding, metal injection moulding (MIM), fineblanking and forming, laser cutting, pressing, fineblanking and moulding tools, from design and toolmaking to the manufacturing of fineblanking tools and formingtools.

With the most diverse test procedures in quality management, we ensure compliance with the required quality features for every precision part manufactured.

Request quote

For the production of your individual precision parts we have a wide range of manufacturing technologies with modern machinery.at our Furtwangen headquarters – in the heart of Baden-Wuerttemberg.

REINER® contract manufacturing covers all relevant manufacturing processes for zinc die casting, injection moulding, metal injection moulding (MIM), fineblanking and forming, laser cutting, pressing, fineblanking and moulding tools, from design and toolmaking to the manufacturing of fineblanking tools and formingtools.

With the most diverse test procedures in quality management, we ensure compliance with the required quality features for every precision part manufactured.

Request quote

You are here:

Advantages at a glance

Made in Germany

One of the few manufacturers that produces all product lines "Made in Germany" is REINER®.

One of the few manufacturers that produces all product lines "Made in Germany" is REINER®.

Everything from one source

From design and toolmaking of fine blanking dies and forming tools to all relevant manufacturing processes.

From design and toolmaking of fine blanking dies and forming tools to all relevant manufacturing processes.

Certified

The REINER® quality system has been certified according to DIN EN ISO 9001 since 2001.

The REINER® quality system has been certified according to DIN EN ISO 9001 since 2001.

Over 100 years of experience

At the company headquarters in Furtwangen, innovative products have been created with Black Forest precision for over 100 years that are in demand worldwide.

At the company headquarters in Furtwangen, innovative products have been created with Black Forest precision for over 100 years that are in demand worldwide.

Casting process

As a forming process for various materials, injection molding has established itself primarily in plastics. However, our processing in this method also includes tin and metal.

With the production of micro and complex parts, we can serve almost all industries and apply these processes in a wide area. Our range of different casting processes will meet all requirements – there are almost no limits to the possibilities.

With the production of micro and complex parts, we can serve almost all industries and apply these processes in a wide area. Our range of different casting processes will meet all requirements – there are almost no limits to the possibilities.

Almost unlimited design freedom

learn more

Metal Injection Moulding

Metal Injection Moulding

Almost unlimited freedom of design

learn more

The optimal alternative for aluminium die-casting

learn more

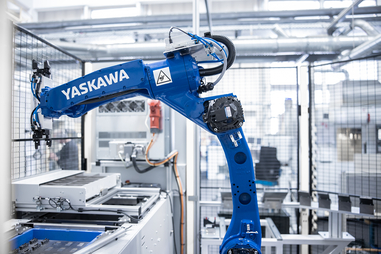

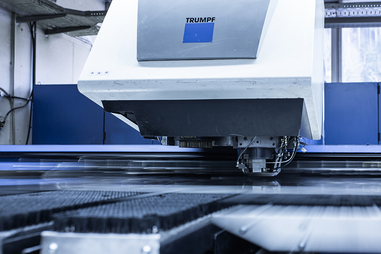

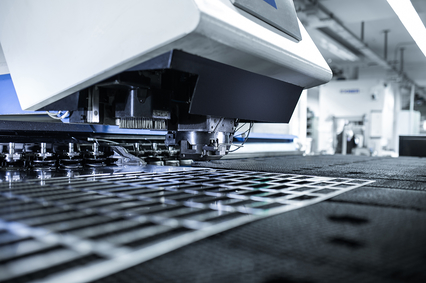

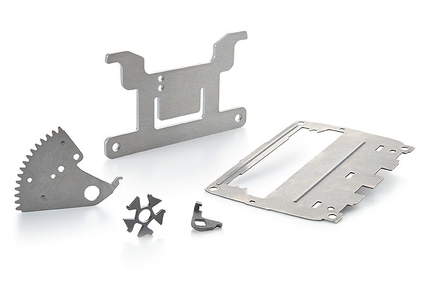

Punching technology

The integration of several manufacturing processes in one operation is decisive for all types of stamping technology. Due to our origins in manufacturing for our own product portfolio, we are very familiar with the optimization and individual production of high-precision parts.

We serve all application areas of precision mechanics and thus ensure optimal production processes. In addition to punching technology, laser cutting is also part of our manufacturing portfolio - no punching tool is required here, the application is based solely on computer control.

We serve all application areas of precision mechanics and thus ensure optimal production processes. In addition to punching technology, laser cutting is also part of our manufacturing portfolio - no punching tool is required here, the application is based solely on computer control.

High processing speeds with extremely precise cuts

learn more

Pressing

PressingPunching technology at the highest level – from tool design to the finished part

learn more

REINER® precision cutting with forming technology

learn more

Innovative Tool Construction – Competence from One Source

learn more

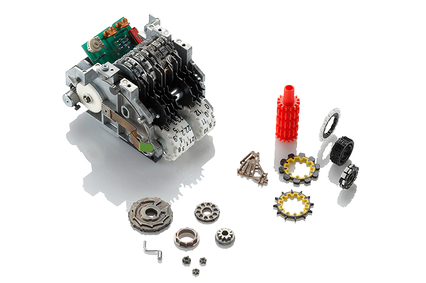

Assembly production

Many customers benefit from our full-service competence and quality management in the assembly of ready-to-install assemblies. The outsourcing of component production simplifies logistics and increases quality in the production process. Concentrate on your core competence and take advantage of costs and competitive advantages by streamlining your own production lines.

We are specialised in small series production up to medium series production, and that at an optimal cost-benefit ratio. Our outstanding specialists manufacture for you professionally and under the most modern production conditions. Thanks to our many years of experience and comprehensive know-how in design and precision parts manufacturing, we can serve a wide range of industries: Our customer portfolio ranges from mechanical engineering and medical technology to electronics manufacturers. In close cooperation with our customers, we develop and manufacture individual precision technology solutions. Benefit from our full service potential and our profound quality thinking.

We are specialised in small series production up to medium series production, and that at an optimal cost-benefit ratio. Our outstanding specialists manufacture for you professionally and under the most modern production conditions. Thanks to our many years of experience and comprehensive know-how in design and precision parts manufacturing, we can serve a wide range of industries: Our customer portfolio ranges from mechanical engineering and medical technology to electronics manufacturers. In close cooperation with our customers, we develop and manufacture individual precision technology solutions. Benefit from our full service potential and our profound quality thinking.

Assembly services - simplifies logistics and increases quality

learn more

Video

REINER® Präzisionstechnik from the Black Forest with the special quality claim. Learn more in the video über the manufacturing of Präzisionsteilen at REINER®.

Learn about the process steps of the individual technologies:

• Zinc die casting

• MIM (Metal Injection Moulding)

• Fine blanking

• Toolmaking for fine blanking dies and forming tools

and üconvince yourself of our premium quality.

REINER® Präzisionstechnik from the Black Forest with the special quality claim. Learn more in the video über the manufacturing of Präzisionsteilen at REINER®.

Learn about the process steps of the individual technologies:

• Zinc die casting

• MIM (Metal Injection Moulding)

• Fine blanking

• Toolmaking for fine blanking dies and forming tools

and üconvince yourself of our premium quality.

What distinguishes REINER® from other companies in precision parts contract manufacturing?

Ernst REINER® GmbH & Co.KG in Baden-Wuerttemberg is itself a manufacturer of precision mechanical products and has always relied on its own in-house tool production and parts manufacturing facilities. At our company not only theory and knowledge of tool making meet demanding daily production practice. The manufactured precision parts also have to prove themselves in the end product and the market gives direct feedback on the quality and precision of the manufactured products.

We live the entire value chain of product success, from the idea to each individual part to marketing. This characterises our thinking and acting in the overall context and forms a unique service portfolio from which our customers in all industries profit, even in the tiniest precision part of contract manufacturing. Our own claim to the highest quality is not only based on industry standards for a production part, but is always carried out with a view to your product success. Perhaps our precision part is only one of a hundred in your product. But you can rely more than 100% on a REINER® precision part.

REINER® Precision Technology – Ideas precisely put into shape

We live the entire value chain of product success, from the idea to each individual part to marketing. This characterises our thinking and acting in the overall context and forms a unique service portfolio from which our customers in all industries profit, even in the tiniest precision part of contract manufacturing. Our own claim to the highest quality is not only based on industry standards for a production part, but is always carried out with a view to your product success. Perhaps our precision part is only one of a hundred in your product. But you can rely more than 100% on a REINER® precision part.

REINER® Precision Technology – Ideas precisely put into shape

You are here:

Service & Support

Technical advice

The complexity of the part requires technical advice?

We are happy to be there for you.

The complexity of the part requires technical advice?

We are happy to be there for you.

Request a quote

Would you like to receive a quote?

Simply fill out our ready-made form.

Would you like to receive a quote?

Simply fill out our ready-made form.

Callback

Would you like us to call you back?

Leave your callback request. We will call you back as soon as possible.

Would you like us to call you back?

Leave your callback request. We will call you back as soon as possible.

Downloads

Do you need more information about our services?

Here you will find further information.

Do you need more information about our services?

Here you will find further information.

You are here:

Contact & Offer

Do you have any questions or need more information?

We look forward to hearing from you!

Request a quote

We look forward to hearing from you!

Request a quote