You are here:

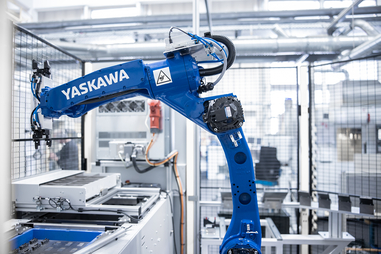

Punching technology

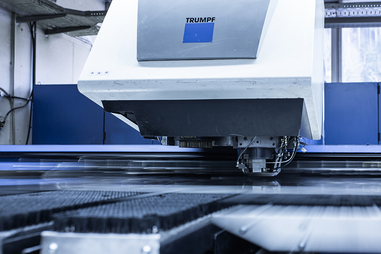

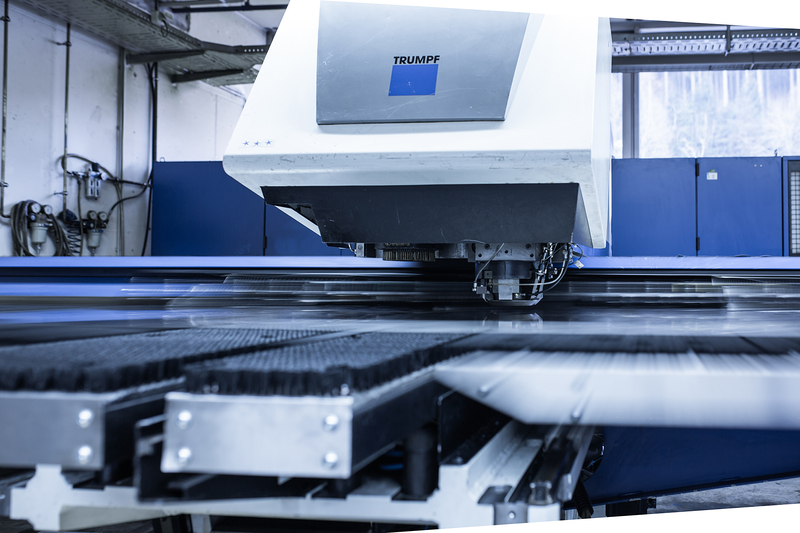

Laser cutting

High processing speed with extremely precise cutting

Laser cutting involves cutting through plate-shaped material with a laser. At REINER®, this involves sheets, stainless steel or aluminum with a thickness of 0.5 mm to 4 mm. A focused and high-energy laser beam is directed at these plates, which is so intense that the material melts and vaporizes upon impact until the metal is penetrated and the cut is made. The resulting metal vapor is blown out using special gases and high pressure.

Laser cutting

Laser cutting

Pressing

Metal pressing in full service for your project

Our company has a dedicated tool shop and design segment for production of pressing and bending tools. Many years of experience in sheet metal processing enable us to develop high-quality and efficient tools. Our contract manufacturing area for metal processing meets our customers’ requirements precisely and at a reasonable price.

We are able to efficiently perform complete and end processing of parts at our site with state-of-the-art CNC machining centres to ensure high quality and accuracy of your pressed and bent parts.

Pressing

We are able to efficiently perform complete and end processing of parts at our site with state-of-the-art CNC machining centres to ensure high quality and accuracy of your pressed and bent parts.

Pressing

Fine cutting/forming

Perfect geometries without reworking

The metal stamping process enables large volumes of flat components to be manufactured from sheet metal at low unit cost. This is done at a high speed, where large presses with one cutting tool can punch many parts simultaneously from one sheet.

In modern practice, pressing combines fine blanking with forming of the metal piece. For this reason, the term "fineblanking/forming" has become established throughout the industry as a dual term for this manufacturing process. The particular economic efficiency of this manufacturing process results from the completion of three to four work steps in one pressing operation

Fine cutting/forming

In modern practice, pressing combines fine blanking with forming of the metal piece. For this reason, the term "fineblanking/forming" has become established throughout the industry as a dual term for this manufacturing process. The particular economic efficiency of this manufacturing process results from the completion of three to four work steps in one pressing operation

Fine cutting/forming

Fine blanking and forming tools

Innovative toolmaking - competence from a single source

REINER® is itself a manufacturer of precision mechanical products and has always relied on its in-house tooling production for fine blanking and forming tools. Here at the company, the theory and knowledge of toolmaking meets the hard daily production practice of parts manufacturing and provides direct feedback on the quality and precision of the tools produced.

Fine blanking and forming tools

Fine blanking and forming tools

You are here:

Contact & Offer

Do you have any questions or need more information?

We look forward to hearing from you!

Request a quote

We look forward to hearing from you!

Request a quote