News from precision technology

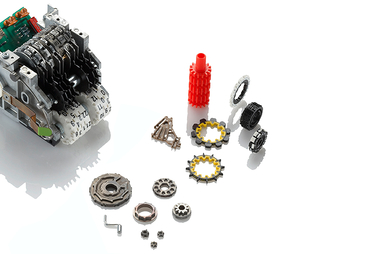

Hybrid component for lifting elements in scanners:

Hybrid component for lifting elements in scanners: Innovative fusion of metal and plastic

In addition to versatility, innovation is a top priority in the field of precision technology:

The spindle nut, an essential component for our REINER® scanners, relies on advanced hybrid production.

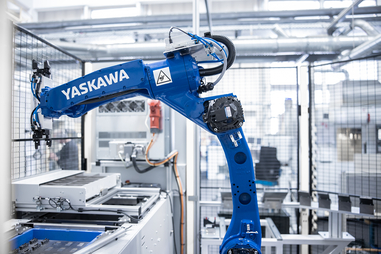

New milling automation with Yaskawa robot in our Chiron FZ15W

New milling automation with Yaskawa robot in our Chiron FZ15WOur new milling automation system, the Chiron FZ15W, revolutionizes milling automation with the use of a state-of-the-art Yaskawa robot. This innovative machine offers efficient and precise part production thanks to a wide range of advanced features.

REINER® wishes you a MERRY CHRISTMAS

REINER® wishes you a MERRY CHRISTMASWe would like to cordially thank you for your good cooperation and the trust you have placed in us and our work. We wish you health, joy and happiness, along with many beautiful moments, in the new year.

REINER® SUMMER PARTY 2022

REINER® SUMMER PARTY 2022Good mood, optimal weather and excellent food evoked beaming faces and happy guests at this year's REINER® summer party as well.

Together with the city of Furtwangen and other companies, we invite you and your family to an information evening. This will take place on November 18 from 4 to 9 pm. We will welcome you at the main entrance at Baumannstr. 16 in Furtwangen.

Glad you were there!

Glad you were there!Many thanks for the numerous visitors at the vocational training fair in Furtwangen.

On Saturday, May 07, we were finally able to present the training opportunities at REINER® again in a presentable manner.

The REINER trainees and instructors had many interesting conversations with the students and their parents and teachers.

REINER® presents: REINNOlab

REINER® presents: REINNOlab Have you heard about the REINNOlab? The new innovation lab from REINER®?

At the company headquarters in the middle of the Black Forest, a small energetic team is working on the topics of tomorrow: innovation, digitalization, sustainability, equality, individualization and technology. The starting signal for the open innovation lab was given two years ago.

Just as we regularly review and optimize our products, we have also relaunched our website. With a new design, our online presence is now more user-friendly, modern and intuitive.

Best mood, celebratory jubilees and great music made the REINER® summer festival a great event – of course in compliance with the applicable Corona rules.On Friday, September 17, the entire workforce was invited to the Summer festival from 12 noon on the large parking lot to spend an informal afternoon.

Our trainees present in the video the jobs in which we train. Maybe your dream job is among them?At REINER® are school graduates exciting apprenticeships and attractive future opportunities open.

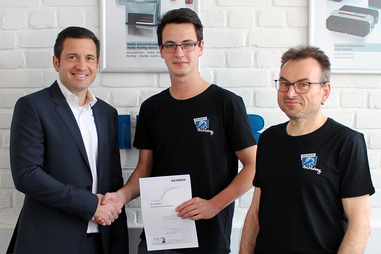

REINER® is one of the outstanding training companies in the southern Black Forest. The company's own apprentice workshop makes a fundamental contribution to a successful future by training and promoting qualified workers.Now Marco Duffner, the next apprentice, joins the ranks of the many skilled workers who have been trained at REINER®.

REINER® precision technology is your competent production partner for bespoke precision parts made of a plethora of materials. Submit your query with the simplified digital form.

Health and well-being are two goals that marking specialist REINER® from Furtwangen has committed to. The company encourages its employees, who were able to get some advice and suggestions for a healthy lifestyle at the health day 2020, to practice a health-conscious conduct.

REINER® trainee builds mini football tablesTrue to the motto “learning by doing”, the prospective industrial mechanics of the stamping and marking specialist Ernst REINER®, proved his skills acquired up to now.

Customers all over the world know REINER® as one of the market leaders in the hand stamp segment.But did you know that REINER® is also a manufacturer of high-quality precision parts?

The REINER® football team participated in the indoor football tournament of the works teams in Furtwangen.The 49th edition of the renowned indoor football tournament of the works teams was played on Saturday, 18 January 2020.

The marking specialist REINER® can now be found on LinkedIn – one of the largest international professional platforms. Followers will receive current news, career opportunities, reports on product innovations and industry insights.

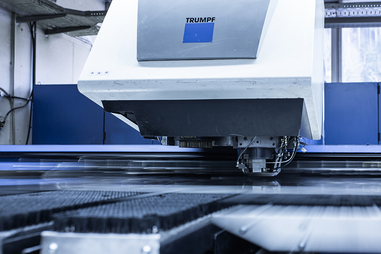

Since the development of semiconductor lasers in the 1960s, the idea of the power of light has been inspiring the inventive spirit of mankind.REINER® has also firmly integrated laser cutting into its product portfolio.

We at REINER® are not afraid to put old methods aside in order to always offer our customers the latest technical standard with our products. Our design engineers have therefore taken a closer look at the manufacturing process of our stamp wheels.

When the good is so close, why wander into the distance?Year after year, the Otto Hahn Gymnasium's education fair at our Furtwangen site proves that recruiting young talent also works directly on site. Our apprentices and their trainers participated again this year with great enthusiasm.

...especially when it comes to training. This is evident in the brand new trainee T-shirts. The shirts come with a specially designed trainee logo and the slogan “Training with us is REINER® success” and are a real eye-catcher.

REINER® apprentice Bernd Dorer receives very good diplomaThe 4th year of apprenticeship last month was the day for many apprentices to complete their training. With his very good final grade, REINER® apprentice Bernd Dorer stood out among them in a special way.

To keep the balance of producing quickly, cost-effectively and with high quality requires a certain sensitivity. The manufacturing professionals of REINER® have this sensitivity and they work constantly on optimising the assembly production of precision parts and adapting it precisely to customer requirements.

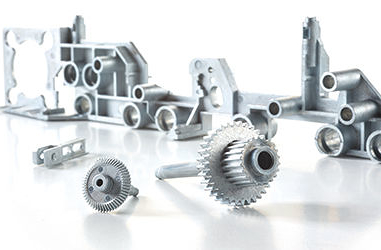

Yes, since MIM produces complex precision parts without machining. The MIM technology "metal injection moulding" offers entirely new freedoms in dimensions, geometry and materials.

Yes. The Precision Parts, Mould Making and Sub-assemblies Suppliers division is constantly developing positively. It was originally developed to meet our highest demands for precision and economy for our own products.

Why should I use zinc die-casting when there's also aluminium die-casting?

Why should I use zinc die-casting when there's also aluminium die-casting?The REINER® zinc die-casting method gives you the greatest design options with highest precision. More still: our individual solutions are much more economically efficient in small and medium-sized series!

REINER® precision cutting with concurrent forming technology offers high piece numbers at low unit costs.Large and powerful presses will punch many parts from a sheet with a cutting tool, at precise dimensions with tear-in- and tear-off-proof cutting edges.

REINER® participated in the "Zukunft jetzt" training fair at the Otto-Hahn Gymnasium with a great positive response

Learn everything about the production options of REINER® precision technology.Let us present the individual procedure and process steps to you, from innovative design to high-quality parts.

The joint film and marketing project includes eight product and application clips that will soon be available online. The students of the "digital media" department of HFU have intensively dealt with the projects since spring 2017 in cooperation with the responsible persons at REINER®.

A century ago, Ernst REINER® laid the foundations for a company that has in the meantime become the global leader in the areas of metal stamps and cheque scanners.