You are here:

Why should I use zinc die-casting when there's also aluminium die-casting?

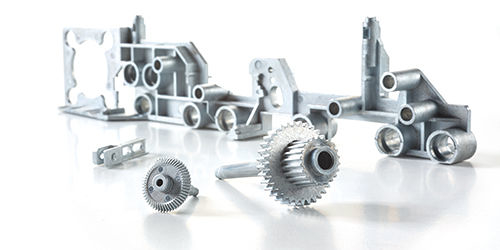

The REINER® zinc die-casting method gives you the greatest design options with highest precision.

More still: our individual solutions are much more economically efficient in small and medium-sized series!

More still: our individual solutions are much more economically efficient in small and medium-sized series!

Design or no design

Our zinc die-casting specialists are happy when things get technically exciting. They love to cast extremely delicate, thin-walled and technically high-quality parts with dimensions of 400 x 600 mm, tool clamping area.

Powerful in the long run

We use hot-chamber die-casting machines with a clamping force of 5- 125 tons. We rely on tried and tested materials only: Z410 / GD-ZNAL4CU1.

Result

Zinc die-casting is the optimal alternative for aluminium die-casting – in particular in delicate and geometrically highly complex parts.

» Find detailed information about zinc die-casting here

Our zinc die-casting specialists are happy when things get technically exciting. They love to cast extremely delicate, thin-walled and technically high-quality parts with dimensions of 400 x 600 mm, tool clamping area.

Powerful in the long run

We use hot-chamber die-casting machines with a clamping force of 5- 125 tons. We rely on tried and tested materials only: Z410 / GD-ZNAL4CU1.

Result

Zinc die-casting is the optimal alternative for aluminium die-casting – in particular in delicate and geometrically highly complex parts.

» Find detailed information about zinc die-casting here