You are here:

Print barcode

Creating barcodes with REINER® marking systems

Print barcode

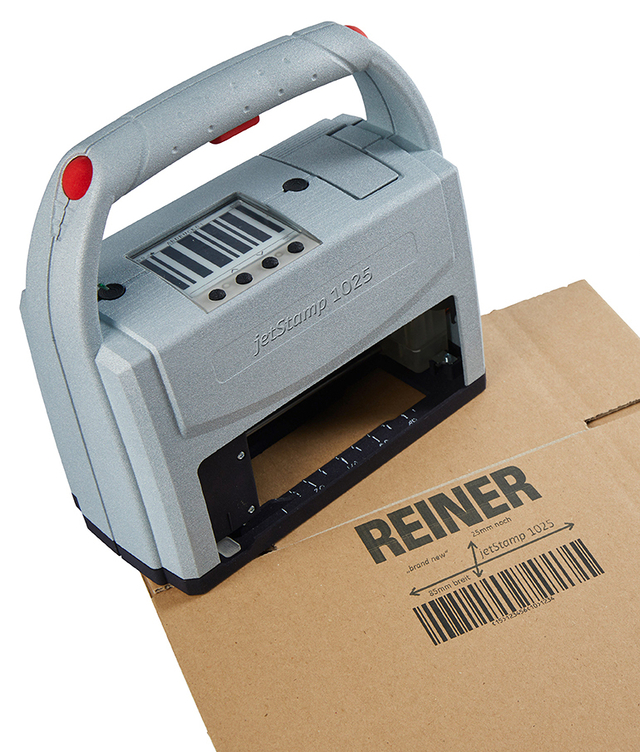

Digital barcode printer machines apply the barcode directly to goods and packaging

Some still remember how we admired the memory of the ladies at the ALDI cash registers: how they quickly wiped any product of the assortment off the checkout belt with one hand and typed in the price with the other - without a price label on the packaging! Since the turn of the millennium, the scanner cash registers have also conquered this discounter and the so-called EAN code, the best-known type of several established barcodes, can no longer be missing on any product.

Meanwhile, barcodes not only simplify shopping, but also entire production processes and logistics management in trade and industry. But regardless of the environment in which the barcodes are to be scanned, the print quality and the stored code must function immediately. The quality of the barcode has become a critical success factor in various process chains.

The mobile inkjet printers from REINER® have proven themselves reliably as barcode printing machines for many years and combine a multitude of special features in a single device:

- Direct printing of many barcode types on individual parts, products, packaging, cardboard boxes

- Barcode printing on paper, cardboard, metal, plastic, glass, curved surfaces, coated labels and almost all smooth surfaces

- Ideal for marking both fixed and sequential barcodes

- The barcode can be created quickly and easily on the PC using the PCset graphic software supplied

- The barcode printing systems jetStamp® 1025 and jetStamp® graphic 970 allow data transfer through Windows based programs like Word, Excel as well as through barcode label software or ERP systems

Meanwhile, barcodes not only simplify shopping, but also entire production processes and logistics management in trade and industry. But regardless of the environment in which the barcodes are to be scanned, the print quality and the stored code must function immediately. The quality of the barcode has become a critical success factor in various process chains.

The mobile inkjet printers from REINER® have proven themselves reliably as barcode printing machines for many years and combine a multitude of special features in a single device:

- Direct printing of many barcode types on individual parts, products, packaging, cardboard boxes

- Barcode printing on paper, cardboard, metal, plastic, glass, curved surfaces, coated labels and almost all smooth surfaces

- Ideal for marking both fixed and sequential barcodes

- The barcode can be created quickly and easily on the PC using the PCset graphic software supplied

- The barcode printing systems jetStamp® 1025 and jetStamp® graphic 970 allow data transfer through Windows based programs like Word, Excel as well as through barcode label software or ERP systems

Barcode marking: what is a barcode?

As the English term barcode implies, it is about the graphic representation of data as an arrangement of parallel bars and gaps of different widths. This barcode can be read contactlessly via optical reading devices such as barcode scanners or cameras. Depending on the standard, the amount of data is limited to a defined set of numbers or character-number combinations, the unique "code" that can be used to recognise and identify the product by computer. Once this barcode has been scanned and recognised by the software, the stored information may be read out of a database and then processed. The 13-digit EAN number is known, for instance, from the reverse of books. There, the EAN barcode contains the ISBN number to determine the title and price, but depending on the software also stock levels, contents descriptions, photos and much more.

The barcode can nowadays be found by anyone shopping in a supermarket when paying at the scanner checkout. The employees pull the goods with the barcode quickly across a glass plate, the barcode scanner underneath confirms the successful identification with a beep and automatically enters the name and price into the cash register. Worldwide standardization is a prerequisite for identifying consumer products unambiguously by EAN code (or in the USA by UPC code). Today, barcodes are essential markings for production control and administration, especially in industry and warehousing.

The barcode can nowadays be found by anyone shopping in a supermarket when paying at the scanner checkout. The employees pull the goods with the barcode quickly across a glass plate, the barcode scanner underneath confirms the successful identification with a beep and automatically enters the name and price into the cash register. Worldwide standardization is a prerequisite for identifying consumer products unambiguously by EAN code (or in the USA by UPC code). Today, barcodes are essential markings for production control and administration, especially in industry and warehousing.

REINER® product solutions

The right device for almost every requirement.

We offer different inject printers depending on your needs and area of application.

Select the right marking device for you from our product variety:

To the handheld inkjet printer

Which barcode types are there?

EAN Barcode

The "European Article Number" (EAN) has its origin as European standard, but can be seen worldwide in the labelling of consumer products. When creating an EAN barcode, it is important to note that it only allows numeric characters.

UPC Barcode

The "Universal Product Code" was the North American pioneer of all commercial, standardised barcodes and is used in the USA mainly in the trade. As with the EAN number, only numeric characters are used to generate the UPC barcode.

Code 128 Barcode

This barcode takes its designation from the significantly extended character range, which can be represented with it: it is the complete ASCII 128 character set.

Thus not only the numbers 0-9, but all Latin letters from a - z and A - Z as well as various special characters like # $ % & () etc. can be coded.

Code 128 is mainly used in the logistics and transport industry.

IT F Barcode

The "Interleaved 2 of 5" (ITF) code was developed for more robust use on packaging materials such as cardboard, as it can usually still be read even with poor print quality. It also supports the entire ASCII character set and always consists of 14 characters.

The "European Article Number" (EAN) has its origin as European standard, but can be seen worldwide in the labelling of consumer products. When creating an EAN barcode, it is important to note that it only allows numeric characters.

UPC Barcode

The "Universal Product Code" was the North American pioneer of all commercial, standardised barcodes and is used in the USA mainly in the trade. As with the EAN number, only numeric characters are used to generate the UPC barcode.

Code 128 Barcode

This barcode takes its designation from the significantly extended character range, which can be represented with it: it is the complete ASCII 128 character set.

Thus not only the numbers 0-9, but all Latin letters from a - z and A - Z as well as various special characters like # $ % & () etc. can be coded.

Code 128 is mainly used in the logistics and transport industry.

IT F Barcode

The "Interleaved 2 of 5" (ITF) code was developed for more robust use on packaging materials such as cardboard, as it can usually still be read even with poor print quality. It also supports the entire ASCII character set and always consists of 14 characters.

Creating a barcode and printing it on any surface

Before the barcode generation a fundamental question must be clarified: are items or packaging only to be labelled for the purpose of more rational internal organisation within the company, e.g. production and storage? Or should the barcode also be identifiable outside the company, e.g. in trade and logistics?

As soon as the code leaves the company and is intended to ensure clear identification, especially in the global market, a central EAN code issuing office is required. Only via this central administration can it be queried which manufacturer and which product in which variant is behind the sequence of numbers. The only official issuing authority in Germany is the company "GS1 Germany". It ensures a syntactically correct article number that does not have any overlaps worldwide.

Once the required barcode type and the number or character sequence to be used have been clarified, the barcode graphic is generated with appropriate software and then printed. If it is a mass product, the strip code is usually integrated into the product or packaging design.

More difficult to handle are sequential or individual barcodes, which have to be adapted with each imprint. If the marking is also to be carried out on site, e.g. in the warehouse or production facility, only two economically viable solutions are possible:

the printing of labels that are glued on, or the more elegant solution using a mobile barcode generator machine.

As soon as the code leaves the company and is intended to ensure clear identification, especially in the global market, a central EAN code issuing office is required. Only via this central administration can it be queried which manufacturer and which product in which variant is behind the sequence of numbers. The only official issuing authority in Germany is the company "GS1 Germany". It ensures a syntactically correct article number that does not have any overlaps worldwide.

Once the required barcode type and the number or character sequence to be used have been clarified, the barcode graphic is generated with appropriate software and then printed. If it is a mass product, the strip code is usually integrated into the product or packaging design.

More difficult to handle are sequential or individual barcodes, which have to be adapted with each imprint. If the marking is also to be carried out on site, e.g. in the warehouse or production facility, only two economically viable solutions are possible:

the printing of labels that are glued on, or the more elegant solution using a mobile barcode generator machine.

REINER® MarkingPartner in your area

Are you looking for an authorized dealer near you? Simply enter your country and postal code and the nearest marking partners will be displayed, like AUTOMATED MARKING INC. in the USA.

To REINER® MarkingPartner

Are labels suitable for sequential barcodes or can a barcode be directly printed on a product?

Labels have many disadvantages. They are complex to use and require at least three work steps: 1. Printing the labels, 2. detaching it from the label carrier and 3. applying it precisely to the object. Self-adhesive labels may peel off or become illegible, especially in humid environments. The design and printing of the labels is also very complex and may impair the product image.

The mobile REINER® marking devices are a smart alternative and perform barcode printing in one step.

Place the barcode stamp machine and apply the barcode to the goods at the push of a button – done! The robust handheld inkjet printer models jetStamp® 1025 and jetStamp® graphic 970 do this job reliably and reasonably priced. The barcode generator and printer allow you to print barcodes on packaging quickly and easily.

Simply generate the desired barcode with a few mouse clicks using the supplied software. The device can even process the following 3 barcode types, Interleaved 2/5, Code 39 and Code 128 b,sequentialy.

If necessary, activate the "sequential" function and automatically generate serial numbers as barcodes.

The mobile REINER® marking devices are a smart alternative and perform barcode printing in one step.

Place the barcode stamp machine and apply the barcode to the goods at the push of a button – done! The robust handheld inkjet printer models jetStamp® 1025 and jetStamp® graphic 970 do this job reliably and reasonably priced. The barcode generator and printer allow you to print barcodes on packaging quickly and easily.

Simply generate the desired barcode with a few mouse clicks using the supplied software. The device can even process the following 3 barcode types, Interleaved 2/5, Code 39 and Code 128 b,sequentialy.

If necessary, activate the "sequential" function and automatically generate serial numbers as barcodes.

How can a barcode be printed and applied to metal, glass and plastic?

For particularly smooth surfaces, REINER® has developed a quick drying ink that remains water and smudge-proof immediately after printing. The innovative technology of the handheld inkjet printer jetStamp® 1025 ensures an airtight closing of the ink nozzles when not in use and is therefore 100% mobile. This prevents them from drying out and keeps these mobile barcode machines functional at all times, even during long interruptions.

So, who invented the barcode and since when is it standard?

The first patent for a barcode technology dates back to 1952 and was invented by Norman Joseph Woodland and Bernard Silver. In the 1970s, the US supermarket chain Walmart was the driving force behind the establishment and ultimately worldwide distribution of barcodes. It used its market power and exerted pressure on product manufacturers to print the Universal Product Code (UPC) on their products in order to rationalise cashing. A few years later, in 1973, the "European Article Number" (EAN) was introduced as a counterpart in Europe.