Application Notes

Our products are used to optimise work in many companies around the world.

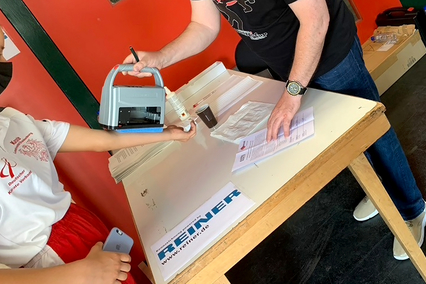

The REINER® marking devices find flexible uses in inbound goods, logistics and production areas alike. They can be used anywhere within a company's production chain, e.g. to label inbound delivery receipts or produced parts. Usage options are unlimited. Processes are optimised and error sources minimised.

Learn more about projects already implemented here:

Metzgerei Braun uses the REINER jetStamp® 1025 as a multitool

Metzgerei Braun uses the REINER jetStamp® 1025 as a multitoolLooking for the ideal solution for daily printing tasks, Metzgerei Braun eventually found the jetStamp® 1025.

This marking device’s flexible, mobile usage options now facilitate many processes.

The town of Lüneburg is successfully driving digitisation by setting the tracks for scanning inbound documents even in the central mailroom.

The town of Lüneburg relies on the jetStamp® 1025 from REINER® as a mobile all-in-one solution that permits printing as required.

The Asian users, known as digitisation pioneers, are optimising data handling for new arrivals with the REINER jetStamp® graphic 970.

An entry stamp with all data required on the person entering the country can eliminate time-consuming and error-prone queries. This increases general and personal safety and simplifies processes.

The portfolio of the watch manufacturer Hanhart from Gütenbach in the Black Forest includes around 60 different stopwatch models.

Instead of labels, the REINER jetStamp®1025, a mobile inkjet printer, is now used for marking.

The current coronavirus pandemic requires effective hygiene concepts from organisers of events from all areas.

The Banzai Cup 2020, a renowned top-notch karate tournament was no different.

The organisers found an ideal solution with the help of REINER®, a company from the Black Forest.

High-quality marking is important since oil cans are often used where dirt and contamination may severely restrict legibility.EMKA Schmiertechnik GmbH from Bretzfeld relies on „Made in Germany“ for marking with the jetStamp® 792 MP.

The Bulgarian capital city of Sofia is the home of a Würth logistics centre where bulk goods packages are used to sort small parts coming right from production, such as screw nuts, and portion them for customers and trade. For this, the goods are packed in boxes compliant with trade needs. An intact logistics chain requires precise marking of the packaging.

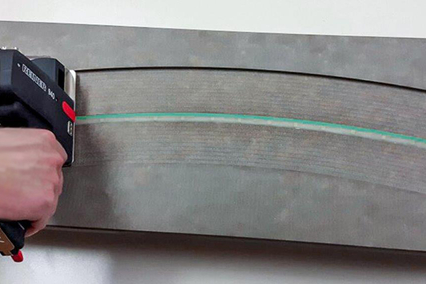

Metal elements are usually marked by marking stamps, engraving, etching or with a laser. Applying the marks and removing them again without residue later is a difficult task.This issue is a thing of the past with the mobile inkjet printer REINER® 940.The marking device is successfully used at NIPPON GOKIN SDN. BHD in Malaysia.

The manufacturer REGUPOL BSW GmbH of gym floors, floorings, footfall sound insulation and many other products made of polyurethane-bound rubber granulate optimised its processes in product marking by converting to use of the REINER jetStamp® graphic 970.

The REINER® 940 is used for marking the finished materials. The mobile inkjet printer permits both mobile and stationary marking of thermosets. It is ideal for printing on large surfaces.

Position and shape of the imprint are kept consistent at Isovolta Gatex GmbH with the help of jigs that hold panel and pipe parts alike in their desired position.

The pallets are often exposed to detrimental conditions in goods transport and must live up to other difficulties as well. Marking is indispensable to meet the global standard specifications of ISPM-15 and to keep an overview of the innumerable pallets in standard and special sizes in circulation.

The REINER jetStamp® 1025 is the key to impeccable marking.

Finding the right connection is important, especially when it comes to the smooth and fast transfer of data in processes. In marking, the focus is on mobility and coupling with the leading systems and their data.

In order to find the best solution for data transfer from SAP directly to the REINER® marking devices, Ernst REINER® works closely together with the specialists from Advanced Applications.

Würth Elektronik GmbH & Co. KG is a leading manufacturer of PCBs in Europe.

Using the mobile marking unit jetStamp® graphic 970 ensures traceability in the production process.

The imprint, comprising a machine-readable DataMatrixCode and the batch ident no. in plain text, permits a reliable labelling solution that is visible and unique at all times.

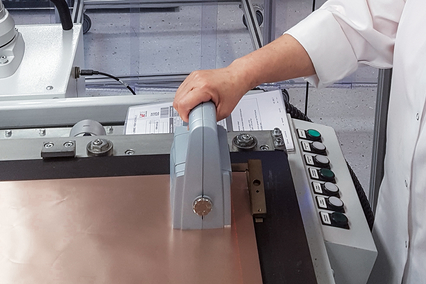

The gate supports and optimises the inbound goods process with two work steps. It is integrated into a workflow system and ensures correct assignment of documents to goods.

This is where the employees of MeisterWerke took action to create pragmatic improvement: Optimisation of logistics bottlenecks in inbound goods skilfully combined with demands for accelerated processes for servicing suppliers and forwarders.

No matter if individual or serial production – an optimal finishing processing for each product is developed.

Innumerable work processes are applied for this, requiring complete documentation during the order and marking for trackability of the parts.

These framework conditions in turn are the perfect area for use of the handheld inkjet printer REINER® 940!

As it was starting to prepare for the global exhibition in 2015, Italian railway company Trenitalia was looking for a way to devalue the many different ticket types quickly and traceably.

The REINER® mobile inkjet printer speed-i-Jet 798, which can be pulled across the ticket like a marker pen, gave the Italian state railway company the right solution for this large event.

The REINER jetStamp® 790 will put a professional imprint onto the coffee bags of Maya placed next to the roaster right at the site of filling.

The filling and expiration dates are provided automatically by the mobile printer on site once it has been programmed. A single movement of a hand prints two dates onto the bags filled with beans still warm from roasting. The process requires no interim storage or label printing.

Who doesn‘t know them: The slim muesli boxes from mymuesli?

Any mix is possible on the customer‘s request, no matter how small the quantity. However: It must remain recognisable clearly and unmistakably at all times.

The REINER® 940 handheld inkjet printer provides good and most of all customised services

in this area.

Together with REINER®, the partner for marking technology, Ganter Normteile was now able to complete an important step towards improving its warehouse logistics.

The just as logical as smart solution intends for 30 pallets delivered every week no longer having to be placed in storage and picked as of now...