Print from ExcelFast. Simple. Reliable.

Print from ExcelFast. Simple. Reliable.

You are here:

Print from Excel

Print barcodes, data matrix codes, part numbers and more directly from Excel without using labels!

Process optimisation in production: cost-effective barcode generation in Excel.

Many production companies, and in particular the medium-sized ones, still mark materials and components with the "classic" felt-tip pens and hand stamps, often ignoring that this is a major source of error. Manual marking never produces machine-readable codes either.

This is why process owners, production managers and QM managers often go looking for cost-effective solutions to produce barcodes or data matrix codes on site at the respective workstations. Two questions always come up:

• What system environment will be used to design the machine-readable imprints? Will it be used from a database?

• How can direct printing be done in the end?

The ideal solution:

• is "very simple" throughout,

• has a high degree of automation,

• can be used on any material,

• offers cost-effective printing, and

• ensures reliable label replacement!

This is why process owners, production managers and QM managers often go looking for cost-effective solutions to produce barcodes or data matrix codes on site at the respective workstations. Two questions always come up:

• What system environment will be used to design the machine-readable imprints? Will it be used from a database?

• How can direct printing be done in the end?

The ideal solution:

• is "very simple" throughout,

• has a high degree of automation,

• can be used on any material,

• offers cost-effective printing, and

• ensures reliable label replacement!

Combining REINER® marking devices with the common spreadsheet software Microsoft Excel is a good way to make barcode printing more efficient!

The network-compatible mobile REINER® inkjet printers not only comprise a code generator and mobile printer in a single device, but also allow the user to optimise other process requirements, e.g. by printing right from Excel, or using simple Excel add-ins for Excel barcodes. This combination helps automate marking while reducing typical errors from manual transfer or marking.

A free barcode generator is integrated into the device software on REINER® marking devices.

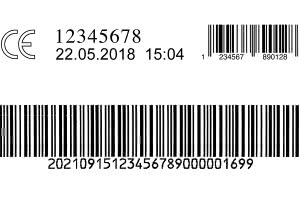

The diverse imprint range of jetStamp® products includes the option of printing freely-adjustable sequential numbers. Date, time or a count can be pre-set and sequentially integrated into the barcode. Combinations with text, figures, numbers or graphics, such as the company logo, are part of the basic functions as well. The desired print images can be designed, administrated and directly printed with the included "PCset graphic" software as desired. The REINER jetStamp® 1025 inkjet printer prints sequential numbers directly just as reliably as it completes any other marking task. The format can be as large as 85 x 25 mm!

What do you do if you need to combine more data? Can additional, further and/or different information be integrated into the data matrix code or the barcode in the scope of work processes, without missing traceability requirements?

A custom, extended programming function permits data transfer from Windows-based programs, e.g. as an Excel macro, an integrated Excel data form (Excel input mask) or an Excel add-in. Sequential lot or batch numbers can be included in 1D or 2D barcodes with their associated additional process data. Barcodes and QR codes are created equally easily in Excel.

Find some practical examples for the vast variety of process information that can be easily provided via a barcode generator or data matrix code generator in Excel below. The final transfer of the QR code from Excel to the mobile REINER® marking device is a breeze at the end. It's become just a simple print job.

Find some practical examples for the vast variety of process information that can be easily provided via a barcode generator or data matrix code generator in Excel below. The final transfer of the QR code from Excel to the mobile REINER® marking device is a breeze at the end. It's become just a simple print job.

Barcode and data matrix code generator for code creation and data transfer to the mobile inkjet printer with an Excel add-in

Industrial production has many interfaces where certain data from the planning and production program are to be printed onto a product. The data may need to be re-imported to identify the component in the following production step, or the product may need to be clearly identifiable for traceability if any faults or complaints occur at a later time. Efficient processing requires machine-readable marking!

REINER® product solutions

The right device for almost every requirement.

We offer different inject printers depending on your needs and area of application.

Select the right marking device for you from our product variety:

To the handheld inkjet printer

Excel barcodes: How can various pieces of information from an Excel table be integrated into a machine-readable 1D barcode?

If the required data are kept in a table or database already, they can be used to create the Excel barcode or data matrix code to match. The code can then be printed easily. Certain workstations may add associated necessary data in the form of additional information. This can be done using an input option or via an existing barcode, followed by review, potential supplementation with further data, and finally conversion into a barcode. Excel as a barcode generator is useful in connection with the REINER® handheld printers.

Microsoft Excel offers many great functions that bring about amazing results very easily. One is its simple input mask to insert data of any kind into tables regularly and recurrently. Finally, one of Excel's many useful add-ins, a barcode generator, will convert the data line into a 1D barcode or into various 2D codes such as data matrix or QR codes.

Microsoft Excel offers many great functions that bring about amazing results very easily. One is its simple input mask to insert data of any kind into tables regularly and recurrently. Finally, one of Excel's many useful add-ins, a barcode generator, will convert the data line into a 1D barcode or into various 2D codes such as data matrix or QR codes.

Direct printing: The benefits of creating changing QR codes with Excel and applying information directly to products.

Specific codes or individual information like the lot number make it possible to trace a product or component back to production. Learning from mistakes is important for technical progress and good, successful products. This makes it necessary to be able to determine the cause of an error, or to "trace it back" to its source.

There are hardly any industrially manufactured products or components without individual numbering or at least a batch number! Large series or industrial production on the assembly line often use laser engraving or stationary printers. Many small series and multi-stage production processes also require marking of workpieces or products. Since this must be done manually, the barcode printer is vital for mobile use in such an environment. Marking must be permanent and machine-readable as far as possible for reliable traceability.

There are hardly any industrially manufactured products or components without individual numbering or at least a batch number! Large series or industrial production on the assembly line often use laser engraving or stationary printers. Many small series and multi-stage production processes also require marking of workpieces or products. Since this must be done manually, the barcode printer is vital for mobile use in such an environment. Marking must be permanent and machine-readable as far as possible for reliable traceability.

How can the barcode generator in Excel cost-effectively create, print and apply barcodes without labels?

Printing labels in Excel, especially with sequential numbers, is an elaborate and error-prone option, even more so if additional production data are to be integrated at different workstations!

A handy marking device from the REINER jetStamp® family uses the part number, lot number or batch number right from Excel. The output range of the final imprint is determined in Excel once using the "Set print area" function. All other settings and combinations of information can be made directly in Microsoft Excel.

A handy marking device from the REINER jetStamp® family uses the part number, lot number or batch number right from Excel. The output range of the final imprint is determined in Excel once using the "Set print area" function. All other settings and combinations of information can be made directly in Microsoft Excel.

REINER® MarkingPartner in your area

Are you looking for an authorized dealer near you? Simply enter your country and postal code and the nearest marking partners will be displayed, like AUTOMATED MARKING INC. in the USA.

To REINER® MarkingPartner

Automation: What other options does Excel offer for automatically importing, combining and printing data?

Excel permits printing of sequential barcodes onto the product with its simple, stable input option. A data form is used to repeatedly enter data into a system. Alternatively, the desired information could also be scanned using a barcode and entered in Excel.

Such data forms are called input masks in Microsoft Excel. They make entering new data into a table or database very easy. Existing data can be edited and searched. All of this has become default functions that do not need any Excel macros or VBA programming at all. Barcode information can usually be imported into Excel with the enclosed barcode reader software (barcode scanner). Excel offers add-ins for the same purpose as well. Pre-existing, manually entered or scanned data from an existing barcode can be turned into a new barcode this way.

The best way of using and combining these many combinations in Excel must be assessed from case to case on site. A successful application example of printing data matrix code efficiently is reflected in our user report on Würth Elektronik. The REINER jetStamp® models print codes directly onto a semi-finished product with an Excel data matrix code generator.

The data matrix code offers a robust and common industry standard for machine-readable identification. Printing data matrix codes has become a standard function of REINER® marking devices, which come with this option even in their most basic form!

Such data forms are called input masks in Microsoft Excel. They make entering new data into a table or database very easy. Existing data can be edited and searched. All of this has become default functions that do not need any Excel macros or VBA programming at all. Barcode information can usually be imported into Excel with the enclosed barcode reader software (barcode scanner). Excel offers add-ins for the same purpose as well. Pre-existing, manually entered or scanned data from an existing barcode can be turned into a new barcode this way.

The best way of using and combining these many combinations in Excel must be assessed from case to case on site. A successful application example of printing data matrix code efficiently is reflected in our user report on Würth Elektronik. The REINER jetStamp® models print codes directly onto a semi-finished product with an Excel data matrix code generator.

The data matrix code offers a robust and common industry standard for machine-readable identification. Printing data matrix codes has become a standard function of REINER® marking devices, which come with this option even in their most basic form!

In production of multi-layered printed circuit boards, employees first scan the data matrix code of the respective move ticket. A USB interface or Bluetooth transfers it to the REINER jetStamp® 970 mobile marking device with a simple Excel macro. The imprints created are applied directly to the various copper layers of what is to become a multi-layered circuit board, giving them one perfectly sharp inkjet imprint each that comprises the machine-readable data matrix code and a part number in plain text. Download the detailed customer reference as an example of semi-automatic mobile marking by Excel macro in our application note "Marking solution for printed circuit board production - DataMatrixCode imprints"

Direct printing of batch and lot numbers onto packaging or product with an Excel macro

Correct and conscientious marking of parts and packaging is part of the everyday processes of our customers and their employees. Typical examples include cosmetics or foodstuffs, where the dates of manufacture or best-before dates, as well as other important data, are used for specific traceability. Mobile printing therefore usually includes batch numbers or lot numbers in the form of letters and digits, almost always supplementing plain-text information as barcode, DMC code or QR code in machine-readable form.

Machine readability requires high-contrast, unblurred print images of the data and resilience against environmental influences. The REINER® marking devices offer this by default, in particular if using quick-drying and smear-resistant special ink! An Excel macro facilitates data transfer to the mobile printer and guarantees accurate marking by employees who work in the production hall or in packaging. Automatically generated print images with precise data reduce errors.

This results in direct transfer of the print image from Excel to REINER®'s mobile handheld inkjet via USB or Bluetooth, avoiding any intermediate steps!

Machine readability requires high-contrast, unblurred print images of the data and resilience against environmental influences. The REINER® marking devices offer this by default, in particular if using quick-drying and smear-resistant special ink! An Excel macro facilitates data transfer to the mobile printer and guarantees accurate marking by employees who work in the production hall or in packaging. Automatically generated print images with precise data reduce errors.

This results in direct transfer of the print image from Excel to REINER®'s mobile handheld inkjet via USB or Bluetooth, avoiding any intermediate steps!

The special features of printing via Excel macro with REINER® marking devices at a glance:

• Saving time by optimising work steps

• Preventing errors by automatic data transfer to the device

• Cost-effective marking by connection to existing software via Excel macro

• Fast printing and transfer

• Marking dimensional, machine-readable codes as well as batch IDs

• Traceability of the produced parts is ensured by clearly legible and smear-resistant marking.

• Preventing errors by automatic data transfer to the device

• Cost-effective marking by connection to existing software via Excel macro

• Fast printing and transfer

• Marking dimensional, machine-readable codes as well as batch IDs

• Traceability of the produced parts is ensured by clearly legible and smear-resistant marking.

Mobile inkjet printers from REINER® offer modern documentation and marking "Made in Germany"!

REINER® offers a hand-held label printer without labels! Employees at incoming goods, in the warehouse or in production alike can set up the labels they need right at their work stations. Stationary printers or label printers are things of the past. "Paper labels" as a consumable are obsolete. The quick-drying REINER® P3-MP3 ink guarantees the best adhesion to a vast variety of materials. In contrast to paper or film labels, it cannot peel off under moisture, oil contamination or abrasion. Economical ink consumption and a long battery life turn the REINER® marking devices into valued team members. A special protective mechanism above the print head ensures that they can patiently take longer work breaks without drying up. All the precision and technical sophistication has gone into REINER® barcode printers for mobile use that stand out for their robustness and reliability.