Print Data Matrix CodeQuick. Simple. Reliable.

Print Data Matrix Code Quick. Simple. Reliable.

You are here:

Print Data Matrix Code

Creating and printing Data Matrix Codes with the REINER® marking systems

Marking your products and parts with mobile DMC printers

Miniaturisation in electronics is part of everyday life for us. Is it possible to print more comprehensive information on a surface that is only three square centimetres large, however?

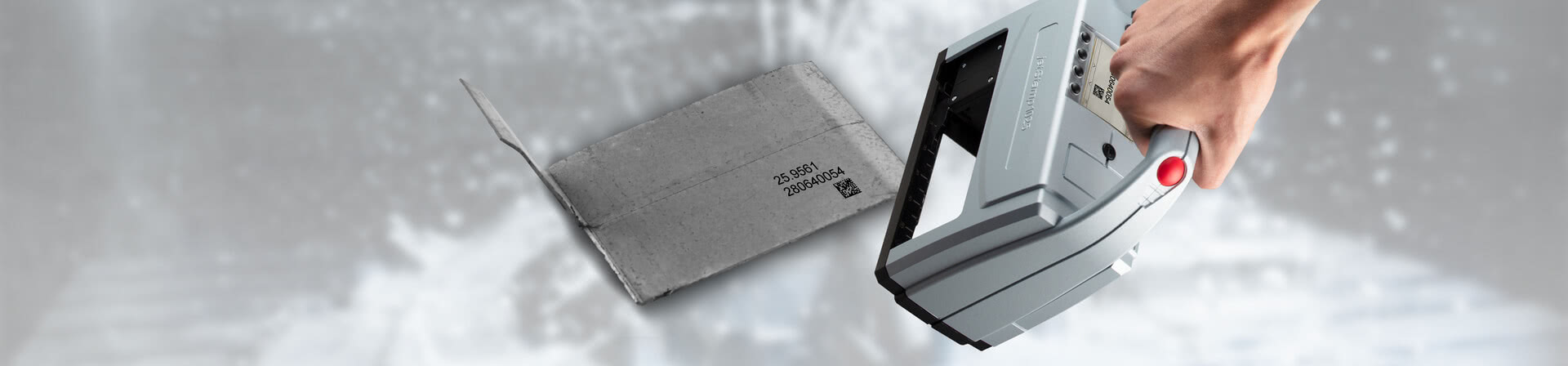

It’s not a problem at all when encoded as a Data Matrix Code (DMC) ist das kein Problem. Only the REINER jetStamp® printers make it possible mobile quickly and efficiently as well, however! Our handy DMC code printers permit flexible marking of products with Data Matrix Codes, as direct printing applies the code right to the product. REINER® special ink is smear-resistant and will remain permanently legible even under difficult circumstances. These prints save time and money as compared to labels, while being much more flexible in product marking.

It’s not a problem at all when encoded as a Data Matrix Code (DMC) ist das kein Problem. Only the REINER jetStamp® printers make it possible mobile quickly and efficiently as well, however! Our handy DMC code printers permit flexible marking of products with Data Matrix Codes, as direct printing applies the code right to the product. REINER® special ink is smear-resistant and will remain permanently legible even under difficult circumstances. These prints save time and money as compared to labels, while being much more flexible in product marking.

REINER® DMC printer: overview of advantages

Direct printing of many DMC types on components, products, packaging, cardboard boxes

Printing the DMC code on virtually any smooth surface made of paper, carboard, metal, plastic, glass, curved surfaces, coated labels

Simply create the DMC right in the device: print images can be transmitted to the device via the enclosed “PCset graphic” software or Windows-based programs such as Word, Excel, or using a barcode label software or ERP system.

Time savings by quick printing and transfer times

Reliable marking and traceability in individual and series production

Reliable marking and traceability in individual and series production

jetStamp® 1025

** NOW ** Printing options of up to 👉 2 inches with corresponding accessories

• 100% mobile

• Large imprint area

• Ideal for small and large objects

• Display guided operation

• Large imprint memory

• Max. print size: 85 x 25 mm (W x H)

• 100% mobile

• Large imprint area

• Ideal for small and large objects

• Display guided operation

• Large imprint memory

• Max. print size: 85 x 25 mm (W x H)

jetStamp® graphic 970

• For medium and small imprint areas

• Diverse imprint options

• Lightweight device

• The device is securely stored and placed well by the station

• Quick print image change

• Max. print size: 65 mm (2 ½”) x 12.7 mm (½”)

• Diverse imprint options

• Lightweight device

• The device is securely stored and placed well by the station

• Quick print image change

• Max. print size: 65 mm (2 ½”) x 12.7 mm (½”)

REINER® 940

• Ideal for large and curved surfaces

• Long imprint area

• Mobile or stationary marking

• Imprint also possible by pulling motion

• Suitable for left- and right handed users

• Max. print size: 140 mm (5 ½”) x 12.7 mm (½”)

• Long imprint area

• Mobile or stationary marking

• Imprint also possible by pulling motion

• Suitable for left- and right handed users

• Max. print size: 140 mm (5 ½”) x 12.7 mm (½”)

REINER® product solutions

The right device for almost every requirement.

We offer different inject printers depending on your needs and area of application.

Select the right marking device for you from our product variety:

To the handheld inkjet printer

Printing the Datamatrix Code: simpler and more economically efficient with the REINER® inkjet printers

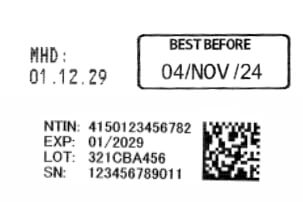

The Data Matrix Code with its compact dimensions is a popular digital marking method that easily permits semi- or fully automated communication between the analogue and digital worlds, contributing to seamless documentation of product processing or transport.

Many operations apply the shape, which is visually related to the data matrix code, to parts and goods fully automated. Smaller companies usually still do this manually. The traditional approach is using labels to apply DMCs to products. These in turn are tedious and time-consuming to print and apply. REINER®’s mobile printers now make it possible to use that working time more productively.

Many operations apply the shape, which is visually related to the data matrix code, to parts and goods fully automated. Smaller companies usually still do this manually. The traditional approach is using labels to apply DMCs to products. These in turn are tedious and time-consuming to print and apply. REINER®’s mobile printers now make it possible to use that working time more productively.

Insbesondere für kleine und mittlere Betriebe sind unsere mobilen DMC-Code-Drucker interessant. REINER® InkJets wurden speziell dafür entwickelt, Produkte schnell und unkompliziert zu beschriften: Data Matrix Codes drucken war nie einfacher. Als clevere Alternative zu Etiketten drucken Sie Datamatrixcodes mit unseren Handdruckern per Knopfdruck direkt auf Ihre Waren. Die REINER® DMC-Drucker sind zuverlässig und langlebig und fügen sich flexibel in jedes Arbeitsumfeld ein.

Small and medium-sized enterprises in particular value our mobile DMC code printers. REINER® InkJets have been developed specifically for labelling products quickly and easily. Never has it been easier to create and print DMC codes. Print this smart alternative to labels right onto your goods with the push of a button using our handheld printers. The REINER® DMC printers are reliable and long-lived, fitting flexibly into any working environment.

Small and medium-sized enterprises in particular value our mobile DMC code printers. REINER® InkJets have been developed specifically for labelling products quickly and easily. Never has it been easier to create and print DMC codes. Print this smart alternative to labels right onto your goods with the push of a button using our handheld printers. The REINER® DMC printers are reliable and long-lived, fitting flexibly into any working environment.

Instructions for simply creating DMC codes with the REINER® InkJets

Intuitive operation enables all employees to use our DMC code printers without any long training times, making the prints available wherever they are needed at any given time. An additional Data Matrix Code generator is not needed as the enclosed REINER® software PCset graphic already contains a DMC code generator. Just a few clicks are needed to create your custom datamatrix code that can be transferred to the REINER jetStamp® models by Bluetooth or USB interface

How our marking solution for printing DMC works:

How our marking solution for printing DMC works:

- The enclosed PCset software allows you to create your custom matrix code, and allows you to set consecutive serial numbers as well. The same device can be used to specify barcodes, text, consecutive numbers, and pictures as printing motives.

- Then connect your REINER® DMC code printer with the computer by Bluetooth or USB and transfer your print data.

- Now you can start marking your products.

- Just place the printer on the product and push the print button. Done!

What makes the DMC code structure special?

Since its introduction in the 1970s, the one-dimensional barcode has become established for use on products and packaging world-wide. The barcode was the predecessor of other, and in particular higher-performance, kinds of graphically represented data. All graphical data packages can be read with visual readers and immediately processed further on a computer. Reliability depends on the barcode’s print quality on the product as well as the legibility based on contamination or wear. The EAN barcode does have some weaknesses in this area, as is at times reflected by extended waiting times at the supermarket checkout when the reader at the end of the belt refuses to emit a successful “bleep”.

A clear further development was achieved in the 1980s, when binary information was encoded not only one-dimensionally as a series of bars. Two-dimensional representation as a square or rectangular “chessboard pattern” enormously expanded storage capacity, not only making the DMC code much more compact, but also more informative and robust. Data are now encoded in black and white boxes or as dots with gaps. This consistent symbol size makes the image much more reliable to read and subsequently decode for a scanner.

A clear further development was achieved in the 1980s, when binary information was encoded not only one-dimensionally as a series of bars. Two-dimensional representation as a square or rectangular “chessboard pattern” enormously expanded storage capacity, not only making the DMC code much more compact, but also more informative and robust. Data are now encoded in black and white boxes or as dots with gaps. This consistent symbol size makes the image much more reliable to read and subsequently decode for a scanner.

The data matrix code inventors have additionally included a procedure for error correction, using the “Reed-Solomon algorithm” to permit correct reading of a matrix code after it has been partly destroyed. Such errors can have entirely everyday causes, such as scratches or contamination in transport of a package. Another advantage is in lower requirements to black-and-white contrast between the grid surfaces: a barcode needs a contrast of 80% for reliable legibility by the scanner, while the DMC can do with as little as a 20% brightness difference.

REINER® MarkingPartner in your area

Are you looking for an authorized dealer near you? Simply enter your country and postal code and the nearest marking partners will be displayed, like AUTOMATED MARKING INC. in the USA.

To REINER® MarkingPartner

Where are data matrix codes used?

Their compact dimensions make DMC codes popular as a digital marking method. They can be found on PCBs, medical devices, tools, chemical or biometric analysers, and even replacing stamps on envelopes and parcels.

Another special feature of the DMC code structure simply is that it cannot be read by people without a scanner and software for it, which makes it suitable for storing discrete information in an encoded form as well, e.g., on letters, documents, time cards, personnel files, or inbound goods inspections.

Another special feature of the DMC code structure simply is that it cannot be read by people without a scanner and software for it, which makes it suitable for storing discrete information in an encoded form as well, e.g., on letters, documents, time cards, personnel files, or inbound goods inspections.

Printing data matrix codes on directly is more efficient than using labels

Our mobile DMC code printers combine the special features of 2D codes with particularly simple application on products and packaging. Labels are still often used to mark building elements and products with DMC codes. Labels are, however, tedious, expensive, and error-prone as compared to direct printing. The following items make clear why in particular smaller manufacturers often profit from direct printing of the Data Matrix Code instead of sticking it on.

You are here:

Direct comparison: why direct printing is more economical than label printing

Many companies present labels as the weakest link in the marking process. The following reasons support using direct printing with the mobile handheld printers by REINER® instead:

Speed

Marking with labels requires three works steps: printing, pulling off, and sticking on. Using direct printing instead saves two of these, increasing economic efficiency in the marking process.

Flexibility

Labels once printed may turn out to be outdated or incorrect. Instead of printing new labels then, you can simple change the motive in your REINER® handheld printers and keep on working.

Reliability

Labels do not stick ideally to many surfaces. They are also susceptible to damage by moisture, oil, and wear. Markings applied with REINER® InkJets, in contrast, are highly robust against such effects and can be read in the long term.

Sustainability

Labels and the backing material from which they are pulled are disposable products that have to be disposed of after use. In the long run, this accumulates a considerable amount of waste. The REINER® hand printers do not create any additional waste and are therefore much more sustainable.

REINER® has had its base in Furtwangen in the Black Forest since 1913. It is a market leader of handheld stamps in Europe and of mobile inkjet printers and scan systems in Germany.