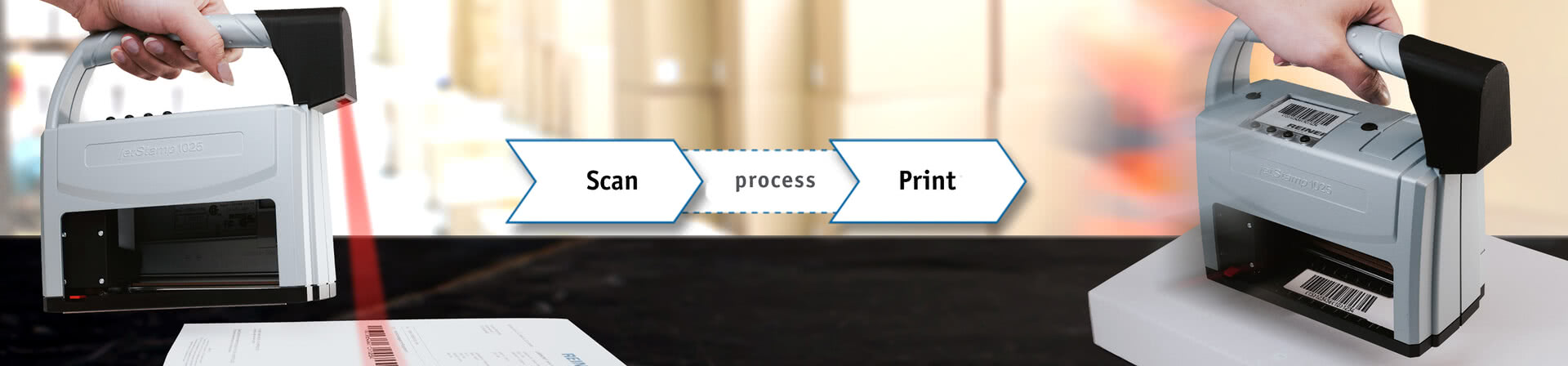

1D & 2D Code ReaderScan. Process. Print.

You are here:

Barcode Reader

Scanning, processing, and directly printing barcodes and data matrix codes

Maximum marking efficiency with REINER®’s mobile printer-scanner solution

Marking often needs to be created and printed based on existing markings in industry, services, and logistics, e.g. when marking parts in plain text rather than barcodes or when marking the outer packaging. Several work steps are typically required for this. First, the existing code needs to be scanned. Subsequently, it must be fed into a database that creates the appropriate new code from it before it finally needs to be applied to the product or packaging safely and reliably.

A single step can replace this time-consuming and error-prone procedure with the help of REINER®’s jetStamp® 1025 sense barcode reader. The barcode reader expands the mobile handheld jetStamp® 1025 sense printer, an industrial scanner that reads barcodes and QR codes quickly and easily. It sends the corresponding information directly to the integrated mobile printer, where a new print image is created based on your presettings. The result can be printed directly on virtually any material or surface.

Overview of the special features of jetStamp® 1025 sense with sensor 1D/2D Code Reader:

A single step can replace this time-consuming and error-prone procedure with the help of REINER®’s jetStamp® 1025 sense barcode reader. The barcode reader expands the mobile handheld jetStamp® 1025 sense printer, an industrial scanner that reads barcodes and QR codes quickly and easily. It sends the corresponding information directly to the integrated mobile printer, where a new print image is created based on your presettings. The result can be printed directly on virtually any material or surface.

Overview of the special features of jetStamp® 1025 sense with sensor 1D/2D Code Reader:

- Efficiency and transparency increase along the entire supply chain while reducing the risk of errors

- Universal application options thanks to a vast range of print images and special REINER® ink for printing on virtually any surface or material

- Easy use due to integrated software functions, robust device, and intuitive operation

- A single device can cover all marking applications

The central role of 1D and 2D barcode scanners in industry and logistics

Safe and cost-efficient marking of goods is important across virtually all industries, through the marking purpose may differ significantly. Multi-stage manufacturing processes, for example, use markings to identify individual components for the corresponding processing steps. Markings are essential for further processing of pallets in the field of warehouse logistics, and unique marking is equally important for traceability in the food industry.

No matter the differences between application areas, they all rely on machine-readable codes that can only be read with a scanner.

The scanner and printer must interact if 1D and 2D codes are to be recreated and printed in the same work step in addition to being read out. REINER®’s jetStamp® 1025 sense barcode reader/printer combines both functions in a single fully mobile industrial application device to save time and costs due to needing only a single device for the entire process.

No matter the differences between application areas, they all rely on machine-readable codes that can only be read with a scanner.

The scanner and printer must interact if 1D and 2D codes are to be recreated and printed in the same work step in addition to being read out. REINER®’s jetStamp® 1025 sense barcode reader/printer combines both functions in a single fully mobile industrial application device to save time and costs due to needing only a single device for the entire process.

REINER® product solutions

The right device for almost every requirement.

We offer different inject printers depending on your needs and area of application.

Select the right marking device for you from our product variety:

To the handheld inkjet printer

Scanning and automatically printing QR codes and barcodes

REINER®’s barcode reader is a scanner that can be attached to another device for virtually any applications. It is equally suitable for 2D codes (data matrix codes) and 1D codes (barcodes), while also being network-compatible in any industrial environment. On top of their functions, our products are always aligned with comfortable handling, which makes our mobile scanner-and-printer solution particularly easy and intuitive to use.

Work steps:

- The 1D and 2D scanners can read any common type of machine-readable code easily and quickly. The powerful 1D/2D code reader handles barcodes, QR codes and data matrix codes equally well.

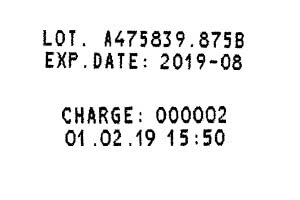

- Now the data received will be processed as desired in the jetStamp® 1025 sense directly. Depending on the setting, the handheld printer will create a new print image in a fully automated process. Time-consuming conversions on a computer, using data processing programs such as Excel, are rendered obsolete, as is the need for connection to an enterprise resource planning system.

- The image can now be applied to the area to be marked. Special REINER® ink means that there are barely any limits to the printing options, as it can be used to print on fabric, glass, cardboard, wood, foils, metals, and many other surfaces. Even curved objects can be easily applied with high-quality print images.

Processing mode options for the scanned codes

REINER®’s mobile printer-scanner combination offers a number of options for processing the scanned codes. The following processing modes can be selected in advance in the free PCset graphic software supplied depending on requirements:

- Scan-Copy-Print: This option will copy a barcode or QR code by printing it unchanged.

- Scan-Convert-Print: This mode converts the code to a different type, e.g. turning a barcode into a QR code. The conversion takes place individually based on the rules specified by the user. This allows, for example, conversion of the barcode on a delivery bill into a different barcode that supports internal logistics.

- Scan-Command-Print: This setting allows conversion of the content of the bar data matrix code read in into a device command. Using a preset “command” print image, jetStamp® 1025 sense users will automatically receive a number of imprint options for the required imprint in various scanning processes. For example, the print image can be selected automatically from among the imprints stored on the device.

REINER® MarkingPartner in your area

Are you looking for an authorized dealer near you? Simply enter your country and postal code and the nearest marking partners will be displayed, like AUTOMATED MARKING INC. in the USA.

To REINER® MarkingPartner

Available applications for the mobile REINER® barcode scanners with printer

REINER®’s robust, lightweight, and mobile printers with scanner blend harmoniously into any existing work environment. Not least due to their very robust build, the printer-scanners can be used as a mobile marking solution in virtually any conceivable working environment. They efficiently link analogue processes to digital applications. Find a number of example industries where our mobile marking solutions have proven themselves below.

Food industry

REINER® marking devices are already popular tools for printing best-before dates. Quality management is of particular relevance when food is handled, and even meticulous control cannot prevent batches from having to be recalled due to quality defects at times. Since consumer health may depend on such recalls, all goods must remain fully traceable. The REINER® barcode scanner represents the ideal method for rendering food marking easier while significantly reducing the risk of errors.

Pharmaceutical industry

Many specifications and laws must be observed in the pharmaceutical industry, both in product manufacture and in proper marking. Patients need to know what they are taking. Pharmacists must mark their medications. Scientists want to keep track of their work in the laboratory. Even minute fluctuations of dosage or quality may change the effect of a drug in some substances and may potentially cause severe harm to the user. Combined with the jetStamp® 1025 sense, the REINER® barcode and Data Matrix Code scanner permits mobile printing and scanning, supporting the user in ensuring secure and error-free marking in such a sensitive industry.

Automotive industry

Efficient processes and manufacturing methods are essential in the highly competitive automotive industry. One key aspect here is the proper marking of components. Since they usually pass through a number of work steps, they must be clearly identifiable throughout this process. Many users prefer REINER®’s mobile marking solutions over labels already as a result. Important information, such as date of manufacture and batch number, can be applied to the product directly. REINER®’s qr code and barcode scanner increases efficiency even further since parts can be scanned and applied with a new print in one and the same work step. Semi-finished- and finished parts can be marked individually and permanently without a single label in sight.

Document management

Documents are applied with a barcode, QR code, or data matrix code in order to increase flexibility and reduce the time required for the individual work steps, simplifying automatic handling of many processes in digitisation. It simplifies digital archiving, gives competent departments access to relevant information more quickly, and allows the retrieval of important data at any time. The mobile scanner scans the printed barcodes or QR codes and proceeds to print them on other documents, envelopes, or invoices or, for example, automatically converts them into plain text.

Industry 4.0

Large investments are not necessary to benefit from the special features of “Industry 4.0” even in small and medium-sized enterprises. REINER®’s mobile inkjets bring digital transformation into SMEs as well to increase automation, networking, and, of course, efficiency across all areas. REINER®’s 1D/2D barcode scanner with integrated printer is the perfect application aid to enable small and medium-sized enterprises to easily integrate products into their digital inventory management and work successfully even at small sales volumes.

Logistics 4.0

Small and medium-sized enterprises make up about 99% of all companies in Germany. The manageable size of this device offers valuable competitive advantages through short decision-making paths and flexibility. REINER® offers flexible marking solutions with its mobile printers and scanners for use in the field and on site to prevent its speed advantage from being reversed by outdated logistics. Scan and print barcodes faster and more flexible than ever. Set out on your digital transformation journey quickly and cost-efficiently and let our marking solutions pave your way to logistics 4.0!

Logistics service providers/contract packers

Brand manufacturers often take over co-packing for other companies as well to improve utilisation of their own packaging capacities. Efficiency of this process is maximised by scanning the goods delivered on behalf of the actual manufacturer with the barcode reader before printing the automatically generated data matrix code directly onto the new packaging or outer packaging. This ensures efficient workflows without any error sources.

Do labels also permit efficient marking of products and packaging?

Many industries continue to use labels to mark their components, products, and packaging, even though this form of marking has a number of disadvantages. Labels are extremely inflexible in their application. A sufficient stock of correct labels must be kept at all times. Spontaneous marking changes generally are not possible. Labels also do not meet the high reliability requirements of permanent marking. They may be rendered illegible or detached due to moisture, dirt, or abrasion, preventing identification or traceability.

Last but not least, labels represent avoidable waste. After all, REINER®’s mobile printer-scanner solution renders them entirely obsolete. Barcodes, data matrix codes, and QR codes, as well as plain text and images, can be printed directly onto the respective products for greatest flexibility in marking that eventually reduces overhead expenses.

Last but not least, labels represent avoidable waste. After all, REINER®’s mobile printer-scanner solution renders them entirely obsolete. Barcodes, data matrix codes, and QR codes, as well as plain text and images, can be printed directly onto the respective products for greatest flexibility in marking that eventually reduces overhead expenses.

What types of machine-readable codes are there for mobile scanning and printing?

There is a general distinction between one-dimensional barcodes and two-dimensional codes that encode information in the form of an area in two dimensions. Find a brief overview of the most common types of codes below.

Barcodes

Everyone knows the conventional barcode from shopping, with data encoded a single direction. This is why this code is referred to as a one-dimensional code. Barcodes come in the following types:

- EAN barcode

- UPC barcode

- Code 128 barcode

- IT F barcode

Data matrix codes

As the name suggests, data in the data matrix code are arranged in the form of a matrix, with a variable size of the boxes from 10x10 to 144x144. This should not be confused with the visually similar QR code. There are two main types of data matrix codes:

- ECC200 data matrix

- GS1 data matrix

REINER®’s 2D/1D barcode scanner and printer permits fast and clean reading of the above code types, rendering the mobile printer with scanner ideal for virtually any industry and application.